In today’s competitive business landscape, branding and functionality often go hand in hand—especially when it comes to display and organizational solutions. Custom acrylic trays have emerged as a versatile staple for B2B buyers across retail, hospitality, office supply, and event industries, offering a unique blend of visual appeal, durability, and customization.

Whether you’re a retail manager looking to showcase cosmetics, a trade show coordinator needing branded display pieces, or an office supply distributor sourcing organizational tools, understanding the nuances of custom acrylic trays—from design fundamentals to cost drivers and buyer pitfalls—can help you make informed decisions that align with your business goals.

This comprehensive guide dives deep into every critical aspect of custom acrylic trays, equipping you with the insights to navigate the buying process, optimize your investment, and select solutions that stand out in your market.

1. What Are Custom Acrylic Trays?

Definition and Core Concept

Custom acrylic trays are specialized storage, display, or organizational tools crafted from acrylic (also known as polymethyl methacrylate, PMMA) that are tailored to meet specific business or end-user requirements. Unlike off-the-shelf trays, which come in standard sizes, shapes, and finishes, custom acrylic trays are designed to fit unique use cases—whether that means matching a brand’s color scheme, accommodating specific product dimensions, or integrating functional features like compartments or branding elements. At their core, these trays leverage the inherent properties of acrylic to deliver a balance of aesthetics and practicality, making them a popular choice for B2B applications where both form and function matter.

Acrylic itself is a synthetic polymer celebrated for its clarity, impact resistance, and versatility—traits that set it apart from other materials like glass, metal, or wood. Custom acrylic trays take these properties a step further by adapting the material to the user’s exact needs, whether that’s a sleek, clear tray for showcasing high-end products or a colored, branded tray for corporate events. The customization process typically involves collaborating with a manufacturer to define specifications like size, shape, edge finish, compartments, and branding, ensuring the final product aligns with the buyer’s functional and aesthetic objectives.

Common Materials and Finishes

While acrylic is the primary material for these trays, not all acrylic is created equal—and the type of acrylic used, along with its finish, can significantly impact the tray’s performance, appearance, and cost. Below are the most common materials and finishes used in custom acrylic tray manufacturing:

• Cast Acrylic: Considered the premium option for custom trays, cast acrylic is made by pouring liquid acrylic monomer into molds. It offers exceptional clarity (often compared to glass), superior impact resistance, and better dimensional stability than other acrylic types. Cast acrylic is also easier to cut, drill, and shape, making it ideal for intricate designs or trays with detailed compartments. It’s commonly used in high-end retail displays, cosmetic trays, and trade show exhibits where visual appeal is a top priority.

• Extruded Acrylic: Extruded acrylic is produced by pushing molten acrylic through a die, resulting in sheets that are more cost-effective than cast acrylic. While it still offers good clarity and durability, it’s slightly less impact-resistant and has narrower tolerances for intricate machining. Extruded acrylic is a popular choice for budget-conscious buyers or trays with simple designs, such as basic office organizers or storage trays for everyday use.

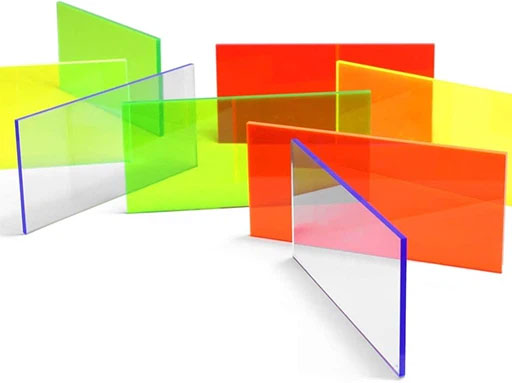

• Colored Acrylic: Both cast and extruded acrylic can be tinted with pigments to create colored trays that align with a brand’s identity or match specific design themes. Common colors include black, white, clear (the most popular), blue, green, and custom Pantone-matched hues. Colored acrylic can be opaque or translucent, depending on the thickness and pigment concentration—translucent options are often used for display trays to add a subtle pop of color without obscuring the products inside.

• Textured Acrylic: Textured finishes are applied to acrylic sheets to enhance grip, hide fingerprints, or add a unique visual texture. Common textures include matte (reduces glare and fingerprints), frosted (creates a semi-opaque, elegant look), and ribbed (improves grip for stackable trays). Textured acrylic is particularly useful for trays used in high-traffic areas, such as retail checkout counters or office break rooms, where durability and ease of maintenance are key.

• Protective Coatings: Many custom acrylic trays include protective coatings to extend their lifespan. UV-resistant coatings prevent yellowing and degradation from sunlight exposure—critical for trays used in retail windows or outdoor events. Anti-scratch coatings add a layer of durability, reducing the appearance of scuffs from regular use. Some manufacturers also offer anti-microbial coatings for trays used in healthcare or food service applications, where hygiene is a priority.

Ready to customize your acrylic trays with the perfect material and finish?

Send us your requirements for a tailored quote today!

2. Why Acrylic Trays Are Widely Used in B2B Applications

B2B buyers consistently choose acrylic trays over other materials for their unique combination of benefits that address key business needs—from enhancing product visibility to reducing long-term costs. Below are the top reasons acrylic trays have become a staple in B2B applications:

Visual Clarity and Product Focus

One of the most significant advantages of acrylic is its exceptional clarity—cast acrylic offers up to 92% light transmission, nearly matching glass but with far greater impact resistance. This clarity makes custom acrylic trays ideal for display applications where the goal is to highlight the product rather than the tray itself. For example, retail stores use clear acrylic trays to showcase cosmetics, jewelry, or electronics, allowing customers to see the product’s details without any visual distractions from the tray. In trade shows, branded acrylic trays with clear bases draw attention to promotional items or samples, ensuring the focus remains on the brand and product.

Durability and Long-Term Performance

B2B buyers prioritize durability, as trays are often used in high-traffic environments (e.g., retail stores, trade shows, offices) where they may be exposed to impacts, scratches, or frequent handling. Acrylic excels in this area: it is 10 times more impact-resistant than glass, meaning it won’t shatter if dropped or knocked over—a critical safety feature for public spaces. Unlike glass, which breaks into sharp shards, acrylic cracks or chips into smooth pieces, reducing the risk of injury.

It does not yellow or degrade easily when exposed to sunlight (especially with UV-resistant coatings), ensuring the tray maintains its appearance over time. This long-term durability translates to lower replacement costs for B2B buyers—acrylic trays can last for years with proper care, whereas glass or plastic trays may need to be replaced more frequently due to damage or wear.

Weight and Handling Advantages

Another key benefit of acrylic is its lightweight nature—acrylic is 50% lighter than glass and significantly lighter than metal or wood. This makes custom acrylic trays easy to transport, set up, and rearrange.

The lightweight nature of acrylic also reduces shipping costs—a major consideration for B2B buyers who may order large quantities of trays. Unlike glass or metal, acrylic trays are less likely to add excessive weight to shipments, lowering transportation expenses and reducing the risk of damage during transit.

Additionally, acrylic’s light weight makes it easier to handle in everyday use—for example, office workers can carry stacked acrylic organizers without difficulty, and retail staff can quickly restock trays with products.

3. Key Design Factors for Custom Acrylic Trays

The success of a custom acrylic tray depends heavily on its design—whether it’s functional, visually appealing, and aligned with the intended use. B2B buyers must consider several key design factors when collaborating with a manufacturer to ensure the final product meets their needs. Below are the most critical design elements to prioritize:

Edge Finishing and Detailing

Edge finishing is often an overlooked but critical design factor for custom acrylic trays. The edges of the tray not only impact its appearance but also its safety and durability. Rough or sharp edges can be a safety hazard, especially in high-traffic environments, while poorly finished edges can detract from the tray’s professional look. Below are the most common edge finishing options for custom acrylic trays:

• Flame Polishing: This is the most popular edge finishing method for acrylic trays. Flame polishing uses a high-temperature flame to melt and smooth the edges of the acrylic, creating a clear, glossy finish that matches the tray’s surface. It’s ideal for clear acrylic trays, as it enhances the tray’s overall clarity and gives it a premium, seamless look. Flame polishing is recommended for trays used in retail displays or trade shows, where appearance is a top priority.

• Diamond Polishing: Diamond polishing uses a diamond-tipped tool to grind and smooth the edges of the acrylic, resulting in a matte or semi-gloss finish. This method is more durable than flame polishing and is ideal for trays that will be exposed to frequent handling or impacts, such as office organizers or storage trays. Diamond-polished edges are also less likely to show scratches than flame-polished edges.

• Beveled Edges: Beveled edges are cut at an angle (typically 45 degrees) and polished, adding a touch of elegance to the tray. This finish is commonly used in high-end cosmetic trays, jewelry displays, or corporate gifts, where aesthetics are a key selling point. Beveled edges can be combined with flame or diamond polishing for a more refined look.

• Rounded Edges: Rounded edges (also known as bullnose edges) are smooth and curved, eliminating sharp corners and reducing the risk of injury. This finish is ideal for trays used in environments with children, healthcare facilities, or high-traffic retail areas. Rounded edges can be polished or left unpolished, depending on the desired appearance.

In addition to edge finishing, buyers should also consider detailing like corner joints and seam placement. Acrylic trays are typically assembled using glue (acrylic cement) or hardware (e.g., screws, rivets). Glued joints are more seamless and visually appealing, but they may be less durable than hardware joints for heavy-duty use. Hardware joints are stronger but can detract from the tray’s appearance if not properly concealed. Buyers should work with their manufacturer to choose the right joint type based on the tray’s intended use and aesthetic goals.

Compartments and Internal Structure

The internal structure of a custom acrylic tray—including compartments, dividers, and slots—determines its functionality. B2B buyers must design the internal structure to accommodate the specific products or items the tray will hold, ensuring organization and ease of use. Below are key considerations for compartments and internal structure:

• Compartment Size and Shape: Compartments should be sized to fit the intended items with minimal wasted space. For example, a cosmetic tray for lipsticks would have narrow, cylindrical compartments, while a tray for office supplies might have rectangular compartments for pens, paperclips, and sticky notes. Buyers should provide the manufacturer with detailed dimensions of the items the tray will hold to ensure a perfect fit.

• Dividers and Removable Inserts: Dividers are used to create compartments and can be fixed or removable. Fixed dividers are more durable and suitable for trays with a consistent use case, while removable inserts allow for flexibility—buyers can adjust the compartment sizes to fit different items. Removable inserts are particularly valuable for office organizers or trade show trays that may need to accommodate various products.

• Depth and Capacity: The depth of the tray and its compartments depends on the size of the items being stored. Shallow compartments are ideal for small items like jewelry or cosmetics, while deeper compartments are better for larger items like office tools or promotional products. Buyers should also consider the tray’s overall capacity—how many items it can hold at once—especially for retail or trade show applications where inventory turnover is high.

• Drainage and Ventilation: For trays used in wet environments (e.g., food service, healthcare), drainage holes or slots are essential to prevent water buildup. Ventilation slots can also be added to trays that hold items that need to stay dry, such as electronic accessories or promotional materials. Buyers should specify these features if the tray will be exposed to moisture.

The internal structure should also be designed to maintain the tray’s stability. For example, a tray with multiple small compartments should have reinforced dividers to prevent bending or warping, while a large, deep tray may need a bottom reinforcement to support heavy items. Buyers should work with their manufacturer to ensure the internal structure is both functional and durable.

Branding and Customization Options

For B2B buyers, custom acrylic trays are often a branding tool—they help promote the company’s logo, colors, or message to customers, clients, or event attendees. There are several branding and customization options available, and buyers should choose the ones that align with their brand identity and marketing goals:

• Logo Engraving or Etching: Engraving or etching the company logo onto the acrylic tray creates a permanent, professional look. Engraving involves cutting the logo into the acrylic surface, while etching uses chemicals or sandblasting to create a frosted design. Both methods are durable and ideal for high-end trays, such as corporate gifts or trade show displays. Buyers should provide the manufacturer with a high-resolution logo file (e.g., vector file) for the best results.

• Screen Printing or Digital Printing: Screen printing or digital printing allows buyers to add full-color graphics, logos, or text to the tray. Screen printing is ideal for large quantities and simple designs, while digital printing (e.g., UV printing) is better for intricate designs or small batches. Printed designs are less durable than engraved or etched designs, so they are best suited for trays that won’t be exposed to heavy wear or frequent cleaning.

• Color Matching: As mentioned earlier, acrylic can be tinted to match a brand’s specific colors (e.g., Pantone shades). Color matching is a great way to reinforce brand identity and create a cohesive look across all marketing materials. Buyers should provide the manufacturer with the exact color code to ensure accurate matching.

• Custom Shapes: Custom acrylic trays can be cut into any shape, not just standard rectangles or squares. Buyers can choose a shape that aligns with their brand (e.g., a tray shaped like the company’s logo) or the intended use (e.g., a circular tray for perfume bottles). Custom shapes add a unique touch and help the tray stand out in a crowded market, but they may increase production costs and lead times.

Ready to customize your acrylic trays with the perfect material and finish?

Send us your requirements for a tailored quote today!

4. Functional Considerations That Buyers Often Overlook

While design and aesthetics are important, B2B buyers often overlook functional considerations that can impact the tray’s usability and longevity. These overlooked factors can lead to costly mistakes—for example, a tray that slips easily on a countertop or is difficult to clean. Below are the most critical functional considerations to keep in mind:

Stability and Anti-Slip Performance

Stability is a key functional requirement for any tray, especially those used in high-traffic environments or on smooth surfaces (e.g., retail counters, office desks). A tray that slips or tips over can damage products, cause injuries, or create a messy display. To ensure stability, buyers should consider the following:

• Base Design: The tray’s base should be wide enough to distribute weight evenly and prevent tipping. A narrow base may be unstable if the tray holds heavy items or is placed on an uneven surface. Buyers should also consider the base’s shape—round or rectangular bases with a low center of gravity are more stable than tall, narrow bases.

• Anti-Slip Pads: Anti-slip pads (e.g., rubber feet, silicone strips) are a simple but effective way to improve the tray’s grip on smooth surfaces. These pads should be placed on the bottom corners of the tray to prevent slipping and reduce noise when the tray is moved. Anti-slip pads are particularly important for trays used in retail stores, where customers may bump into displays, or offices, where desks are often smooth and polished.

Cleaning and Maintenance

Custom acrylic trays are often used in environments where hygiene is important (e.g., food service, healthcare, cosmetics), so ease of cleaning and maintenance is a critical functional consideration. Acrylic is generally easy to clean, but certain designs or finishes can make maintenance more difficult. Below are key factors to consider:

• Smooth Surfaces: Trays with smooth, non-porous surfaces are easier to clean than those with textured or porous surfaces. Textured surfaces can trap dirt, dust, and grime, making them harder to wipe down. Buyers should choose a smooth finish (e.g., clear, matte) for trays that will be cleaned frequently.

• Fingerprint Resistance: Acrylic is prone to fingerprints, which can make the tray look dirty and unprofessional. To reduce fingerprints, buyers can choose a matte or textured finish, or request an anti-fingerprint coating. Anti-fingerprint coatings are a thin layer applied to the acrylic surface that repels oil and dirt, making the tray easier to maintain.

Buyers should also consider the tray’s durability in relation to cleaning—frequent cleaning can wear down finishes over time, so choosing a durable finish (e.g.,

5. Typical Application Scenarios

Custom acrylic trays are versatile and can be used in a wide range of B2B applications. Below are the most common scenarios where acrylic trays excel, along with examples of how they are used and key design considerations for each:

Retail and Cosmetic Displays

Retail and cosmetic industries are the largest users of custom acrylic trays, as they rely on visually appealing displays to attract customers and showcase products. Acrylic trays are ideal for these applications because of their clarity, durability, and customization options. Common uses include:

• Cosmetic Trays: Acrylic trays are used to display lipsticks, eyeliners, mascaras, foundations, and other cosmetic products. These trays often have custom compartments sized to fit specific product dimensions and may include branding elements like engraved logos or colored acrylic matching the brand’s palette. Key design considerations: clear or frosted acrylic for product visibility, anti-fingerprint coatings, and beveled edges for a premium look.

• Jewelry Trays: Acrylic trays are used in jewelry stores to display rings, necklaces, bracelets, and earrings. They may have soft, padded compartments (e.g., velvet-lined) to protect delicate jewelry and clear acrylic sides to showcase the products. Key design considerations: shallow compartments, rounded edges for safety, and a stackable design for storage.

• Electronics Accessories Trays: Retailers selling phone cases, chargers, headphones, and other electronics accessories use acrylic trays to organize and display these small items. These trays often have removable dividers to accommodate different-sized accessories and may include printed graphics highlighting product features. Key design considerations: durable edges, anti-slip pads, and easy-to-clean surfaces.

In retail applications, the goal is to create displays that are eye-catching and easy for customers to navigate. Custom acrylic trays allow retailers to tailor their displays to their brand and product lineup, ensuring a consistent and professional look across the store.

Office and Household Organization

Custom acrylic trays are also used in office and household organization, as they offer a sleek, modern way to organize small items. B2B buyers in the office supply and home goods industries often source acrylic trays for their customers. Common uses include:

• Office Organizers: Acrylic trays are used on desks to organize pens, pencils, paperclips, sticky notes, and other office supplies. These trays often have removable dividers to allow for customization and may be colored or branded with the company logo. Key design considerations: durable, easy-to-clean surfaces, and a stackable design for storage.

• Drawer Organizers: Acrylic trays are used inside drawers to organize silverware, utensils, makeup, or office tools. These trays are often shallow and have multiple compartments to separate different items. Key design considerations: non-slip base, easy to fit into standard drawer sizes, and durable edges.

• Household Storage Trays: Acrylic trays are used in bathrooms, kitchens, and bedrooms to store toiletries, spices, jewelry, and other household items. These trays are often clear or colored to match the decor and may have textured finishes to hide fingerprints. Key design considerations: water-resistant, easy to clean, and a stable base.

In office and household applications, the goal is to create functional, aesthetically pleasing organizers that help users stay organized. Custom acrylic trays allow buyers to tailor the design to the needs of their customers, whether that’s a budget-friendly office organizer or a high-end bathroom tray.

6. Custom Acrylic Trays vs. Other Tray Materials

B2B buyers often compare custom acrylic trays to trays made from other materials like glass, metal, wood, or plastic. Each material has its own advantages and disadvantages, and the choice depends on the tray’s intended use, budget, and aesthetic requirements. Below is a detailed comparison of custom acrylic trays vs. other common tray materials:

Acrylic Tray vs. Glass Trays & Metal Tray & Wood Tray

|

Factor

|

Acrylic Trays | Glass Trays | Metal Trays | Wood/Composite Trays |

| Clarity | Excellent (92% light transmission, slightly less than glass but still clear) | Superior (95% light transmission, the clearest material available) | Industrial, opaque (hides products, better for storage) | Warm, natural, opaque (ideal for rustic or traditional decor) |

| Durability | High (impact-resistant, resistant to chemicals) | Low (breaks easily, shatters into sharp shards) | Very High (scratch-resistant, corrosion-resistant for stainless steel) | Low (prone to water damage, warping, and scratches) |

| Weight | Lightweight | Heavy (difficult to transport and handle) | Heavy (especially stainless steel) | Heavy (especially solid wood) |

| Customization | High (colored, engraved, printed, custom shapes) | Low (difficult to cut and shape, limited color options) | Moderate (can be engraved or painted, limited shape options) | Moderate (can be painted, stained, or engraved, limited shape options) |

| Cost | Moderate | High (especially for tempered or custom-cut glass) | High (especially stainless steel or brass) | Variable (solid wood is expensive, MDF is budget-friendly) |

| Maintenance | Easy (wipe with mild soap and water) | High (prone to scratches, requires careful handling to avoid breaking) | Moderate (may require polishing to prevent tarnishing, especially brass) | High (requires sealing to prevent water damage, periodic refinishing) |

Not sure which material is right for your B2B project?

Send us your use case, and we’ll help you design the ideal acrylic tray!

7. Manufacturing and Quality Considerations

The quality of custom acrylic trays depends heavily on the manufacturer’s production processes, tolerances, and quality control standards. B2B buyers must work with a reputable manufacturer to ensure the trays meet their specifications and are durable enough for their intended use. Below are key manufacturing and quality considerations to keep in mind:

Production Processes

Custom acrylic trays are manufactured using several key processes, each of which impacts the tray’s quality and cost. Understanding these processes can help buyers make informed decisions about their orders. The most common production processes include:

• Cutting: Acrylic sheets are cut into the desired shape using tools like laser cutters, CNC routers, or table saws. Laser cutting is the most precise method, ideal for intricate shapes or small batches. CNC routing is better for large batches or thick acrylic sheets, while table saws are used for simple, straight cuts. Buyers should choose a manufacturer that uses laser cutting or CNC routing for custom trays to ensure accuracy.

• Shaping: Acrylic can be heated and bent into curved or irregular shapes using a heat gun or bending machine. This process is used to create trays with rounded edges, curved sides, or custom shapes. The quality of the shaping process depends on the manufacturer’s ability to control temperature and cooling time—overheating can cause the acrylic to yellow or crack, while underheating can result in a weak bend.

• Assembly: Acrylic trays are assembled using acrylic cement (glue) or hardware. Acrylic cement melts the surface of the acrylic, creating a strong, seamless bond when it dries. This method is ideal for high-end trays where appearance is key. Hardware assembly (screws, rivets) is stronger but less aesthetically pleasing. Buyers should confirm with the manufacturer which assembly method will be used and request samples to test the bond strength.

• Finishing: As discussed earlier, edge finishing (flame polishing, diamond polishing) is a critical step in the production process. Finishing also includes applying protective coatings (UV-resistant, anti-scratch, anti-fingerprint) and branding elements (engraving, printing). Buyers should specify the desired finish and coatings in their order and confirm that the manufacturer has experience applying these finishes.

Buyers should also ask the manufacturer about their production lead times—laser cutting and CNC routing can take longer than other methods, especially for large batches. It’s important to factor in lead times when planning the order to ensure the trays arrive on time.

Tolerances and Consistency

Tolerances refer to the acceptable variation in dimensions (size, shape, thickness) for the custom acrylic trays. Tight tolerances ensure the trays fit their intended use and are consistent across the order. B2B buyers should specify their tolerance requirements in their order (e.g., ±0.1mm for thickness, ±0.5mm for length and width) and confirm that the manufacturer can meet these tolerances.

Consistency is also important—all trays in the order should be identical in size, shape, and finish. Inconsistent trays can cause problems for B2B buyers, especially if they are used for display or organizational purposes. Buyers should request a sample batch of trays before placing a large order to check for consistency. They should also ask the manufacturer about their quality control processes for ensuring consistency, such as regular dimensional checks during production.

Quality Control Standards

Reputable manufacturers have strict quality control standards in place to ensure the trays meet the buyer’s specifications. B2B buyers should ask the manufacturer about their quality control processes, which may include:

• Incoming Material Inspection: Checking the quality of the acrylic sheets before production (e.g., clarity, thickness, absence of defects like bubbles or scratches).

• In-Process Inspection: Checking the trays during production (e.g., dimensional accuracy, bond strength, edge finishing).

• Final Inspection: Checking the finished trays for defects (e.g., scratches, cracks, uneven finishes, branding accuracy) before shipping.

Buyers should also ask if the manufacturer has any certifications (e.g., ISO 9001) that demonstrate their commitment to quality. ISO 9001 is an international standard for quality management systems, and manufacturers with this certification are more likely to produce high-quality, consistent products.

In addition to quality control standards, buyers should also consider the manufacturer’s customer service. A good manufacturer will communicate regularly with the buyer, provide updates on the order, and address any issues promptly. They should also offer a warranty or guarantee on their products, ensuring the buyer can return or replace defective trays.

8. Cost Structure and Pricing Factors

Understanding the cost structure of custom acrylic trays is critical for B2B buyers looking to optimize their budget and avoid unexpected expenses. The cost of custom acrylic trays depends on several key factors, and buyers should be aware of these factors when requesting a quote from a manufacturer. Below is a breakdown of the cost structure and pricing factors:

How Design Complexity Affects Cost

Design complexity is one of the biggest drivers of cost for custom acrylic trays. More complex designs require more time, labor, and materials, resulting in higher prices. Key design elements that impact cost include:

• Shape and Size: Standard shapes (rectangle, square, circle) are less expensive to produce than custom shapes (e.g., logo-shaped, irregular curves). Larger trays also cost more than smaller ones, as they require more acrylic material.

• Compartments and Dividers: Trays with multiple compartments or removable dividers are more expensive to produce than simple, solid trays. Intricate compartment designs (e.g., curved dividers, small compartments) require more precise cutting and assembly, increasing labor costs.

• Edge Finishing and Detailing: Premium edge finishes like flame polishing or beveled edges cost more than basic finishes like diamond polishing. Additional detailing (e.g., rounded corners, seamless joints) also increases labor costs.

• Branding and Customization: Engraving, etching, and full-color printing are more expensive than simple color matching. Intricate branding designs (e.g., detailed logos, full-color graphics) require more time and materials, increasing cost.

To reduce costs, buyers can simplify their design—for example, using standard shapes, minimizing the number of compartments, or choosing a basic edge finish. However, it’s important to balance cost with functionality and aesthetic goals—simplifying too much may result in a tray that doesn’t meet the intended use.

Order Quantity and Economies of Scale

Order quantity is another major factor in pricing—manufacturers offer volume discounts for large orders due to economies of scale. When buyers order a large number of trays, the manufacturer can spread the fixed costs (e.g., setup fees, tooling costs) across more units, reducing the cost per unit. Below is a general overview of how order quantity impacts cost:

• Small Batches (1–50 units): Higher cost per unit, as fixed costs are spread across fewer units. Small batches are ideal for testing a design or for low-volume applications (e.g., corporate gifts, small trade shows).

• Medium Batches (51–500 units): Lower cost per unit than small batches, as fixed costs are spread across more units. Medium batches are ideal for retail stores or office supply distributors with moderate demand.

• Large Batches (501+ units): Lowest cost per unit, with significant volume discounts. Large batches are ideal for large retail chains, trade show companies, or manufacturers sourcing trays for their products.

Buyers should ask the manufacturer for a volume pricing quote to see how increasing the order quantity can reduce the cost per unit. It’s also important to consider storage costs when ordering large batches—buyers should only order as many trays as they can use or store to avoid wasting money.

Hidden Costs Buyers Should Consider

In addition to the base cost of the trays, B2B buyers should be aware of hidden costs that can increase the total cost of the order. These hidden costs include:

• Shipping and Handling Costs: Shipping costs can be high, especially for large batches or heavy trays. Buyers should factor in shipping costs when comparing quotes from different manufacturers. It’s also important to consider handling costs—some manufacturers charge extra for packaging or special handling (e.g., fragile shipping).

• Sample Fees: Many manufacturers charge a fee for sample trays, especially for custom designs. Samples are important for testing the design and quality, but buyers should be aware of these fees and factor them into their budget. Some manufacturers will refund the sample fee if the buyer places a large order.

• Customization Fees: Additional customization (e.g., rush orders, special coatings, custom colors) may incur extra fees. Buyers should specify all customization requirements upfront and ask the manufacturer if there are any additional fees.

• Defect and Replacement Costs: If the trays are defective or do not meet the buyer’s specifications, the buyer may incur costs for returning or replacing them. To avoid these costs, buyers should work with a reputable manufacturer with strict quality control standards and a clear warranty policy.

To avoid unexpected costs, buyers should request a detailed quote from the manufacturer that includes all fees (base cost, tooling, shipping, samples) and ask for clarification on any unclear charges. It’s also important to have a written contract that outlines the terms of the order, including delivery dates, quality standards, and refund policies.

Looking for a transparent, detailed quote for your custom acrylic tray order?

Contact us now to get started!

9. How to Communicate Requirements to a Manufacturer

Effective communication with the manufacturer is critical for ensuring the custom acrylic trays meet the buyer’s specifications. B2B buyers often make mistakes in early-stage communication that lead to delays, defects, or higher costs. Below are key tips for communicating requirements to a manufacturer, including information to prepare, common mistakes to avoid, and how to work efficiently with experienced factories:

Information Buyers Should Prepare

Before contacting a manufacturer, buyers should gather all relevant information about their custom acrylic tray requirements. This information will help the manufacturer provide an accurate quote and produce trays that meet the buyer’s needs. Key information to prepare includes:

• Detailed Dimensions: Provide the manufacturer with exact dimensions for the tray (length, width, height) and any compartments or dividers. Include tolerances (e.g., ±0.1mm) to ensure accuracy. It’s helpful to provide a diagram or CAD file of the design, as this reduces the risk of miscommunication.

• Material and Finish Specifications: Specify the type of acrylic (cast vs. extruded), thickness (e.g., 3mm, 5mm), color (clear, colored, Pantone code), and finish (flame polished, matte, textured). Also, specify any protective coatings (UV-resistant, anti-scratch, anti-fingerprint) or branding elements (engraving, printing, logo file).

• Intended Use and Environment: Tell the manufacturer how the tray will be used (e.g., retail display, trade show sample tray, office organizer) and the environment it will be used in (e.g., high-traffic, wet, outdoor). This information helps the manufacturer recommend the right material, finish, and design features (e.g., anti-slip pads, drainage holes).

• Order Quantity and Lead Time: Specify the number of trays needed and the desired delivery date. This helps the manufacturer determine if they can meet the lead time and provide a volume discount.

• Budget Constraints: Be transparent about your budget, as this helps the manufacturer recommend cost-saving options (e.g., simplified design, extruded acrylic instead of cast acrylic). However, avoid choosing the cheapest option at the expense of quality—this can lead to higher costs in the long run due to defects or replacements.

Buyers should also prepare any supporting materials, such as logo files (vector files are best), design diagrams, or samples of similar trays. These materials help the manufacturer visualize the buyer’s requirements and reduce the risk of miscommunication.

Common Mistakes in Early-Stage Communication

B2B buyers often make the following mistakes in early-stage communication with manufacturers, which can lead to delays, defects, or higher costs. Avoiding these mistakes is key to a successful order:

• Vague or Incomplete Specifications: Providing vague specifications (e.g., “a clear acrylic tray for cosmetics”) can lead to misinterpretation. The manufacturer may produce a tray that is the wrong size, has the wrong compartments, or uses the wrong material. Always provide detailed, specific specifications to avoid this.

• Not Providing a Logo or Design File: Failing to provide a high-resolution logo or design file can result in poor-quality branding (e.g., blurry engravings, inaccurate colors). Always provide a vector file (e.g., .AI, .EPS) of your logo or design, as this ensures the manufacturer can reproduce it accurately.

• Ignoring Lead Time Realities: Underestimating lead times or demanding unrealistic delivery dates can lead to rushed production, which often results in quality issues. Manufacturers need time to source materials, program machinery, produce samples (if requested), and complete quality control checks. Buyers should discuss lead times upfront and build in a buffer for unexpected delays (e.g., material shortages, shipping delays).

• Overlooking Material Compatibility: Not confirming if the chosen acrylic material or finish is compatible with the tray’s intended use can lead to premature wear or failure. For example, using uncoated acrylic in an outdoor trade show booth can result in yellowing from UV exposure, while using a porous finish in a food service environment can trap bacteria. Buyers should work with the manufacturer to confirm material compatibility for their specific use case.

• Neglecting to Confirm Quality Standards: Failing to clarify quality standards (e.g., acceptable defect rates, finish requirements) upfront can lead to disputes between the buyer and manufacturer. For example, a buyer may expect flawless edges, while the manufacturer considers minor scratches acceptable. Buyers should document quality standards in writing and request a sample to confirm alignment before placing a large order.

• Communicating Changes Inconsistently: Making frequent or last-minute changes to the design, quantity, or specifications—especially through informal channels (e.g., casual emails, phone calls)—can cause confusion and delays. All changes should be communicated in writing (e.g., formal change orders) and confirmed by both parties to ensure everyone is on the same page.

By avoiding these common mistakes, B2B buyers can streamline communication with manufacturers, reduce the risk of delays or defects, and ensure the final product meets their expectations.

Working Efficiently with Experienced Factories

Working with an experienced manufacturer of custom acrylic trays can significantly simplify the buying process and improve the quality of the final product. Below are tips for working efficiently with experienced factories:

• Leverage Their Expertise: Experienced manufacturers have deep knowledge of acrylic materials, production processes, and design best practices. Instead of dictating every detail, buyers should collaborate with the manufacturer and ask for recommendations. For example, a manufacturer may suggest a more cost-effective edge finish that still meets the buyer’s aesthetic goals or recommend a UV-resistant coating for outdoor use. Trusting their expertise can lead to better outcomes and cost savings.

• Request a Detailed Project Timeline: Ask the manufacturer to provide a detailed project timeline that outlines key milestones (e.g., sample approval, production start, shipping date). This helps the buyer track progress and plan accordingly. Regular check-ins (e.g., weekly updates) can also help identify potential issues early and keep the project on track.

• Approval Samples Before Mass Production: Always request a pre-production sample (PPS) before starting mass production. The sample should be identical to the final product in terms of material, finish, dimensions, and branding. Review the sample carefully—check for defects, confirm dimensions, and test functionality (e.g., stability, stackability). Only approve the sample once it meets all specifications to avoid costly rework later.

• Clarify Payment Terms and Conditions: Discuss payment terms (e.g., deposit amount, balance due date) and conditions (e.g., return policy, warranty) upfront. Experienced manufacturers typically require a deposit (20–50% of the total cost) to cover material and setup costs, with the balance due before shipping. Be sure to get all payment terms in writing to avoid misunderstandings.

• Build a Long-Term Relationship: If you anticipate needing custom acrylic trays regularly (e.g., seasonal retail displays, ongoing trade show needs), consider building a long-term relationship with a trusted manufacturer. Long-term relationships often result in better pricing, faster lead times, and priority service. Manufacturers are also more likely to go the extra mile for repeat customers, such as accommodating rush orders or offering custom solutions.

Effective communication and collaboration with an experienced manufacturer are key to delivering high-quality custom acrylic trays that meet your business needs. By preparing detailed specifications, avoiding common communication mistakes, and leveraging the manufacturer’s expertise, you can streamline the buying process and optimize your investment.

Conclusion

Custom acrylic trays are more than just storage or display tools—they’re a strategic asset for B2B businesses looking to stand out in a competitive market. By applying the insights from this guide—understanding design fundamentals, cost drivers, material comparisons, and manufacturer communication best practices—you can make informed decisions that optimize your investment, enhance your brand, and deliver solutions that meet the unique needs of your customers.

Whether you’re a first-time buyer or a seasoned professional, taking the time to research, collaborate with experts, and prioritize quality will ensure your custom acrylic trays deliver long-term value and help you achieve your business goals. As the demand for personalized, functional solutions continues to grow, custom acrylic trays will remain a top choice for B2B buyers seeking to balance form, function, and affordability.

Jayi Acrylic: Your Leading China Custom Acrylic Tray Manufacturer

Jayi Acrylic is a leading professional manufacturer of acrylic trays based in China, dedicated to crafting premium tray solutions that captivate customers and showcase products most appealingly.

With over 20 years of profound experience collaborating with world-leading brands, we deeply understand the critical role of acrylic trays in enhancing product visibility, elevating brand image, and boosting user satisfaction.

Our factory holds prestigious ISO9001 and SEDEX certifications, which stand as solid guarantees for our uncompromising product quality and adherence to ethical manufacturing standards.

We combine industry expertise with innovative design concepts to deliver tailored acrylic tray solutions that perfectly meet the diverse needs of our clients, helping their products stand out in competitive markets.

You Might Also Like Other Custom Acrylic Products

Post time: Jan-23-2026