Acrylic sheet is a very widely used material in our life and home decoration. It is often used in instrumentation parts, display stands, optical lenses, transparent pipes, etc. Many people also use acrylic sheets to make furniture and other items. During use, we may need to bend the acrylic sheet, so can the acrylic sheet be bent? How does the acrylic sheet bend? Below I will lead you to understand it together.

Can The Acrylic Sheet Be Bent?

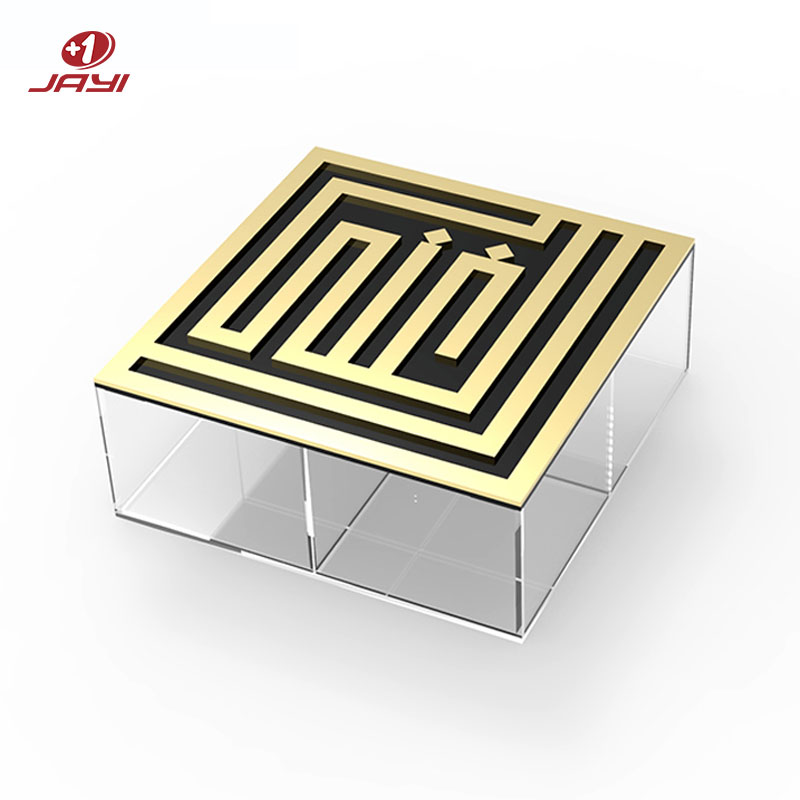

It can be bent, not only can be made into arcs but also can be processed into various shapes. This is mainly because the acrylic sheet is easy to form, that is to say, it can be shaped into the shape required by customers by injection, heating, etc. Generally, many acrylic products we see are curved. In fact, this is processed by hot bending. After heating, acrylic can be hot bent into various arcs with beautiful lines and other irregular shapes. No seams, beautiful shape, can not deform or crack for a long time.

The acrylic hot bending process is generally divided into local hot bending and overall hot bending:

The Partial Acrylic Hot Bending Process

One of the more common types of acrylic display stands is to thermally bend the straight acrylic into an arc, such as a U-shape, semicircle, arc, etc. There are also some troublesome local thermal bending, such as thermally bending the acrylic into a right angle, However, the hot bend is a smooth arc. This process is to tear off the protective film at this hot bend, heat the acrylic edge to be hot bent with a high temperature die rod, and then bend it to a right angle with external force. The edge of the bent acrylic product is a smooth curved right angle.

The Overall Acrylic Hot Bending Process

It is to put the acrylic board into the oven at a set temperature. When the temperature in the oven reaches the melting point of the acrylic, the acrylic board will not slowly soften. Then put on high-temperature gloves with both hands, take out the acrylic board, and place it in advance. On top of the good acrylic product mold, wait for it to cool slowly and completely fit on the mold. After hot bending, the acrylic will gradually harden when it encounters cold air, and it will start to be fixed and formed.

Acrylic Bending Heating Temperature

Acrylic hot bending, also known as acrylic hot pressing, is based on the thermoplastic properties of acrylic, heating it to a certain temperature, and plastic deformation occurs after softening. The heat resistance of acrylic is not high, as long as it is heated to a certain temperature, it can be bent. The maximum continuous use temperature of acrylic varies between 65°C and 95°C with different working conditions, the heat distortion temperature is about 96°C (1.18MPa), and the Vicat softening point is about 113°C.

Equipment For Heating Acrylic Sheets

Industrial Heating Wire

The heating wire can heat the acrylic plate along a certain straight line (for the line), and place the acrylic plate to be bent above the heating wire. After the heating position reaches the softening point of 96°, it is heated and bent along this heating and softening straight line position. It takes about 20 seconds for the acrylic to cool and set after hot bending. If you want to cool it quickly, you can spray cold air or cold water (you must not spray white electric oil or alcohol, otherwise the acrylic will burst).

Oven

Oven heating and bending is to change the surface of the acrylic plate (for the surface), first put the acrylic plate into the oven, and after the overall heating in the oven for a period of time, the acrylic softening temperature reaches 96 °, take out the softened whole piece of acrylic, and put it in the oven. Put it on the pre-made mold, and then press it with the mold. After cooling for about 30 seconds, you can release the mold, take out the deformed acrylic plate, and complete the entire baking process.

It must be noted that the temperature of the oven needs to be controlled and cannot be raised too high at one time, so the oven needs to be preheated in advance, and a special person will take care of it, and the operation can only be performed after the temperature reaches the set temperature.

Precautions For Hot Bending Of Acrylic Sheet

Acrylic is relatively brittle, so it cannot be cold-rolled and hot-rolled, and it will break when cold-rolled, so it can only be heated and hot-rolled. When heating and bending, attention should be paid to controlling the heating temperature. If the heating temperature does not reach the softening point, the acrylic plate will be broken. If the heating time is too long, the acrylic will foam (the temperature is too high and the material will be damaged). change, the inside begins to melt, and the external gas enters the inside of the plate), the blistered acrylic will affect the appearance, and the entire product will be scrapped if it is seriously blistered. Therefore, the process of hot bending is generally completed by experienced workers.

In addition, acrylic hot bending is related to the material of the sheet. Cast acrylic is more difficult to hot bend, and extruded acrylic is easy to hot bend. Compared with cast plates, extruded plates have lower molecular weight and slightly weaker mechanical properties, which is beneficial to hot bending and thermoforming processing, and is beneficial to rapid vacuum forming when dealing with large-sized plates.

In Conclusion

Acrylic hot bending is an indispensable process in acrylic processing and production. As a high-quality acrylic product production factory in China, JAYI acrylic will customize products according to the specific requirements of customers, comprehensively consider which material to choose, and control the heating temperature. Acrylic products with foam, standard size, and guaranteed quality!

Related Products

Post time: May-23-2022