Acrylic boxes outperform glass boxes in durability, boasting superior clarity and flexible designs that have made them a top choice for storage and display purposes. Their light weight and shatterproof features not only make them a safer substitute for glass but also keep them appealing, thanks to their sleek, see-through look.

Cleaning and maintaining these boxes is remarkably simple. They deliver dependable performance for years, whether used in homes, commercial spaces, or retail stores. Coming in numerous shapes and styles, they cater to diverse needs—offering the practicality you need while still retaining a neat, aesthetically pleasing appearance.

What Are the Advantages of Acrylic Boxes?

Acrylic boxes have become a go-to choice for numerous applications, thanks to their attractive appearance, robust strength, and budget-friendly price point. It’s easy to see why their one-of-a-kind qualities deliver practical advantages—serving diverse needs from retail product displays to personal storage setups.

Keep reading to discover the key benefits of acrylic boxes. Let’s break down the advantages that make them an exceptional, wise material selection.

1. Understand Acrylic's Material Properties

Acrylic, chemically known as polymethyl methacrylate (PMMA), is a type of thermoplastic polymer. One of its most remarkable properties is its high transparency. With a light transmittance of up to 92%, it offers a crystal - clear view, often being compared to glass. However, unlike glass, acrylic has a more uniform transparency, without the potential optical distortions that can occur in some types of glass. This makes it an ideal choice for applications where clear visibility of the contents is crucial, such as in high-end product displays in jewelry stores or art galleries.

Moreover, acrylic has a good surface hardness and glossiness. It can maintain a smooth and shiny appearance even after long - term use, which adds to its aesthetic appeal. Its hardness also means that it is more resistant to minor scratches compared to some softer plastics, although it is still not as scratch-resistant as tempered glass.

2. Explore Lightweight Design Benefits

One of the most noticeable advantages of acrylic boxes is their lightweight nature. Acrylic has a relatively low density, which makes these boxes much lighter than their glass counterparts. For instance, a glass box of the same size and thickness would be significantly heavier. This lightweight design offers several practical benefits.

In a retail setting, when setting up product display stands, acrylic boxes are much easier to handle and position. Staff can effortlessly move and rearrange them without straining their muscles or requiring additional equipment for lifting. Similarly, for transportation purposes, whether it's shipping products in acrylic packaging boxes or moving display units between stores, the reduced weight leads to lower transportation costs. Shipping companies often charge based on weight, so using lighter acrylic boxes can result in substantial savings over time, especially for businesses that frequently transport large quantities of goods.

3. Discover High Durability and Impact Resistance

Acrylic boxes are highly durable and possess excellent impact resistance. While glass is brittle and can shatter easily when dropped or hit with force, acrylic can withstand significant impacts without breaking. This makes acrylic boxes suitable for a wide range of applications, both in daily use and in more demanding environments.

In a household, an acrylic storage box used to store children's toys can endure being knocked around without the risk of shattering into dangerous pieces. In an industrial setting, acrylic boxes used for storing small parts or samples can withstand the vibrations and minor collisions that may occur during handling and transportation. Their durability also means that they have a longer lifespan, reducing the need for frequent replacements, which is not only cost-effective but also more environmentally friendly.

4. Review Cleaning and Maintenance Simplicity

Cleaning and maintaining acrylic boxes is a straightforward task. A simple cleaning routine using a mild detergent or soap solution and a soft cloth is usually sufficient to keep them looking clean and clear. Harsh chemicals, such as ammonia-based cleaners or strong solvents, should be avoided as they can damage the surface of the acrylic, causing it to become cloudy or lose its luster.

For example, in a museum where acrylic display cases are used to showcase valuable artifacts, the cleaning process is quick and easy. Staff can simply wipe down the cases regularly to remove dust and fingerprints, ensuring that the artifacts inside are always clearly visible. In a home office, an acrylic document storage box can be easily cleaned whenever it gets dirty, maintaining a neat and professional appearance. Additionally, if there are any stubborn stains, a gentle scrub with a non-abrasive sponge can usually do the trick without scratching the surface.

5. Learn About Design Versatility

Acrylic boxes offer a high degree of design versatility. They can be fabricated into various shapes, colors, and sizes to meet different needs and aesthetic preferences. Through techniques like thermoforming, cutting, and bonding, acrylic can be transformed into anything from a simple rectangular storage box to a complex, custom-shaped display case with curved edges.

In the world of retail, acrylic display boxes come in a wide array of designs. There are multi-tiered acrylic jewelry display boxes with compartments of different sizes to showcase rings, necklaces, and bracelets attractively. For home organization, you can find colorful acrylic storage boxes in various geometric shapes, such as hexagonal or octagonal, that not only serve a practical purpose but also add a decorative touch to the room. Moreover, acrylic can be dyed or tinted to achieve different colors, allowing for seamless integration with different brand colors in commercial settings or home decor themes.

6. Evaluate Cost-Effective Solutions

When considering the cost-effectiveness of acrylic boxes, it's important to look beyond the initial purchase price. While the per-unit cost of an acrylic box may be higher than some other materials, like basic cardboard or low-quality plastic, the long-term savings are significant.

Let's take a look at a cost-comparison example. Suppose a business is considering using either cardboard boxes or acrylic boxes for product packaging. Cardboard boxes are relatively inexpensive upfront, but they are not as durable. They may get damaged during shipping, leading to product returns and additional costs for re-packaging. On the other hand, acrylic boxes, with their durability and resistance to wear and tear, can be reused multiple times.

Over a year, if a business ships 1000 products per month, the cost of replacing damaged cardboard boxes may add up significantly, while the acrylic boxes, despite the higher initial investment, will still be in good condition, resulting in lower overall costs. A cost-comparison chart might show that over 5 years, the total cost of using acrylic boxes is 30% lower than using cardboard boxes when factoring in replacement and damage costs.

7. Consider Safety in Various Applications

Safety is a crucial factor, and acrylic boxes have a distinct advantage in this regard. Due to their shatter-resistant nature, they are much safer to use in many applications compared to glass boxes. In a children's playroom, an acrylic toy storage box is a safer option as it won't break into sharp pieces if it falls or is knocked over.

In public places such as museums, galleries, or shopping malls, acrylic display boxes are preferred for exhibiting valuable items. In the event of an accidental collision, the acrylic box will not shatter and cause injury to bystanders, while still protecting the items inside. This safety feature also extends to industrial settings, where acrylic boxes used for storing hazardous materials or small parts can prevent the spread of dangerous fragments in case of an accident.

8. Analyze UV and Temperature Resistance

Acrylic boxes have a certain degree of UV and temperature resistance. While they are not completely immune to the effects of long-term UV exposure, modern acrylic materials are formulated to be more resistant to yellowing and degradation caused by sunlight. For outdoor applications, such as using acrylic boxes to display information panels or protect products in outdoor vending machines, the UV-resistant properties help maintain the box's clarity and structural integrity over time.

In terms of temperature resistance, acrylic can withstand a wide range of temperatures without significant deformation. Although it has a lower heat-distortion temperature compared to some high-performance plastics, it can still function well in normal indoor and outdoor temperature conditions. For example, an acrylic box used to store gardening tools in a shed can endure the temperature fluctuations between day and night during different seasons without warping or losing its shape.

9. Compare Acrylic to Other Materials

When comparing acrylic to other common materials, such as glass, plastic, and metal, it has both advantages and disadvantages.

|

Material |

Weight |

Strength and Impact Resistance |

Cost |

Aesthetic Appeal |

|

Acrylic

|

Lightweight, about half the weight of glass

|

High impact resistance, much more resistant than glass

|

Medium - high initial cost, but cost-effective in the long run

|

High transparency, good gloss, customizable in color and shape

|

|

Glass

|

Heavy

|

Brittle, low impact resistance

|

Low to medium cost for basic glass, high for specialty glass

|

High transparency, classic look

|

|

Plastic

|

Lightweight

|

Varies by type; some have low impact resistance

|

Low cost for basic plastics

|

Variable transparency and appearance

|

|

Metal

|

Heavy

|

High strength, good impact resistance

|

High cost for some metals like aluminum, medium - high for steel

|

Industrial look, can be painted or finished

|

Acrylic's lightweight nature and high impact resistance set it apart from glass and some plastics. While metal is strong, it is much heavier and often more expensive, and lacks the transparency that acrylic offers.

10. Mitigate Potential Limitations

Although acrylic boxes have numerous advantages, they do have some potential limitations. One common issue is that the surface of acrylic can be scratched relatively easily compared to more scratch-resistant materials like tempered glass. However, there are ways to mitigate this problem.

Applying a protective film during manufacturing or use can help prevent scratches. When cleaning, using only soft, non-abrasive cloths and gentle cleaners is essential. Additionally, some acrylic products are now being treated with special coatings to enhance their scratch-resistance, making them more suitable for long-term use in high-traffic or rough handling environments.

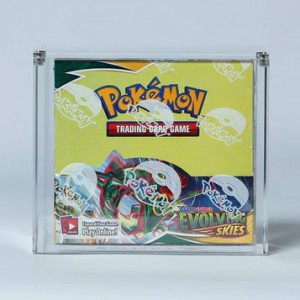

Enhance Product Display and Branding

Acrylic boxes play a pivotal role in enhancing product display and branding. Their high transparency is a key factor that makes them stand out in the world of product presentation. With a light transmittance of up to 92% or even higher in some high-quality acrylic materials, these boxes offer an unobstructed view of the products inside. This is especially crucial for products that rely on their visual appeal to attract customers, such as jewelry, high-end watches, and luxury cosmetics.

Take jewelry display boxes, for example. When a diamond necklace is placed inside an acrylic jewelry display box, the high-transparency acrylic allows the diamond's brilliance and the fine craftsmanship of the necklace to be fully on display. The clear view from all angles enables customers to closely examine the details of the jewelry, from the cut of the gemstones to the quality of the metalwork. This not only showcases the product's features but also creates a sense of luxury and exclusivity. In a jewelry store, well-designed acrylic display boxes can transform a simple necklace into a captivating piece that draws customers in, increasing the likelihood of a purchase.

For electronics, acrylic display boxes can also significantly enhance the product's presentation. A sleek smartphone or a pair of high-tech wireless earbuds displayed in an acrylic box can look more appealing and modern. The clean, transparent appearance of the acrylic box complements the technological aesthetics of the electronics, making them seem more desirable. Brands can also use acrylic boxes to create a branded display experience. By adding the company logo, brand colors, or product-specific graphics to the acrylic box through techniques like silk-screening or UV printing, they can reinforce their brand identity.

In a retail store, a row of acrylic-box-displayed smartphones with the brand logo prominently printed on the boxes creates a cohesive and recognizable brand display. This not only helps customers easily identify the brand but also contributes to a more professional and high-end brand image. Moreover, the design versatility of acrylic boxes allows for creative display solutions. They can be shaped into unique forms, such as multi-tiered structures or custom-shaped cases, to better showcase the products and make the display more eye-catching.

All in all, acrylic boxes are powerful tools for enhancing product display and strengthening brand identity in various industries.

Improve Organization and Storage

Acrylic boxes serve as a cost-efficient option for optimizing storage space, positioning them as a top pick in the jewelry box sector. Beyond their practicality for showcasing content, they also add an elegant, artistic touch to both home and office settings. Boasting a transparent design paired with a user-friendly opening and closing mechanism, these boxes allow for a clear view of what’s inside—doing away with the guesswork often associated with opaque storage organizers. This handy feature saves you valuable time and spares you from unnecessary frustration.

This quality proves especially beneficial in high-activity areas like commercial offices or residential spaces, where easy access to various items is a must. Acrylic display boxes offer a charming way to keep your belongings organized! They work exceptionally well for sorting office supplies, crafting materials, or pantry goods, helping maintain a tidy and efficient space.

Such acrylic containers contribute to smoother office workflows by ensuring that essential items are always well-organized and within reach. Pens, paperclips, and important documents stay orderly and easy to find. These sleek boxes can be nested neatly without losing their structural integrity. Thanks to their rigid yet flexible PMMA construction, they resist warping even when used in harsh or extreme conditions.

When it comes to residential use, acrylic display boxes are just as versatile. They’re excellent for organizing bedroom closets, storing seasonal apparel, or arranging costume jewelry. Incorporating acrylic jewelry storage boxes in your bedroom closet lets you stack drawers, making the most of vertical space. This storage method also comes with the added perk of providing a convenient spot for everyday essentials.

Unlike other plastic storage alternatives, acrylic boxes won’t turn yellow or develop cracks over years of use—making them a durable, long-term investment. Their versatility extends even further to meet a broader range of needs. In commercial kitchens, for example, they function perfectly for organizing utensils and spices exactly how you want.

In bathrooms, they offer a stylish and organized solution for storing toiletries. Their transparency allows them to blend seamlessly with any decor, making them a perfect fit for any environment. What’s more, their eco-friendly properties add to their overall value: acrylic boxes can be recycled and reused at a much faster rate than traditional plastics.

This aligns perfectly with the sustainability goals that many people aim to achieve today. Custom acrylic options—supported by groups like library Friends associations—enable users to create tailored storage solutions, even for unusual or specific needs. For instance, if you’re using an acrylic organizer to store art supplies, you can customize its dimensions or the number of compartments to suit your requirements.

With an annual production volume exceeding 500,000 units, acrylic storage solutions are not only widely available but also budget-friendly, ensuring they remain accessible to a large number of users.

Explore Customization Options

The customization options for acrylic boxes are extensive, making them a popular choice for a wide range of applications. Whether it's for business or personal use, acrylic boxes can be tailored to meet specific requirements in terms of shape, size, color, and printed graphics.

Shape - Acrylic boxes can be fabricated into virtually any shape. From the standard rectangular and square shapes that are commonly used for storage and display, to more complex and unique shapes. For example, a company promoting a new circular-shaped product might opt for a custom-made circular acrylic display box. This not only showcases the product in a more eye-catching way but also creates a distinct brand image. Using advanced manufacturing techniques like laser cutting and thermoforming, the acrylic can be precisely shaped to fit the product perfectly, providing a snug and protective enclosure.

Size - The size of acrylic boxes can be customized to fit any item, regardless of its dimensions. Small-scale businesses selling handmade jewelry can order custom-sized acrylic jewelry boxes that are just the right size to hold their unique pieces. On the other hand, large-scale manufacturers of electronic devices can have acrylic boxes made to fit their bulky products. For instance, a new tablet model can be packaged in a custom-sized acrylic box that not only provides protection during shipping but also makes for an attractive unboxing experience for the customer. The ability to customize the size ensures that there is no wasted space, optimizing both storage and transportation efficiency.

Color - Acrylic boxes can be produced in a vast array of colors. Clear acrylic boxes are popular for their transparency, allowing the contents to be fully visible. However, colored acrylic boxes can add a touch of creativity and brand alignment. A cosmetics brand might choose to have its product display boxes in the brand's signature color, such as a bright pink for a makeup line targeting a young and trendy audience. Additionally, translucent and opaque colors can be used to create different visual effects. A semi-translucent blue acrylic box can give a sense of calmness and sophistication, making it suitable for high-end product displays or luxury gift packaging.

Printed Patterns - Printing on acrylic boxes is another powerful customization option. Businesses can have their logos, brand slogans, product information, or even intricate designs printed on the boxes. Silk-screening is a common method used for printing on acrylic, which can produce high-quality, long-lasting prints. For example, a company commemorating a special event might order acrylic boxes with the event logo and date printed on them. These boxes can be used as giveaway items or as packaging for event-related products. UV printing is also gaining popularity as it allows for more detailed and vibrant prints, enabling the creation of stunning visual effects on the acrylic boxes.

Acrylic Boxes vs. Alternatives

Acrylic boxes outperform alternative options like glass, cardboard, and conventional plastics by a significant margin. What truly distinguishes them from competitors is the powerful combination of their practicality, durability, and versatility. Thanks to these outstanding attributes, acrylic boxes have become a reliable go-to solution across nearly every industry—from retail and cosmetics to electronics.

In the sections below, we’ll break down some of these key qualities of acrylic boxes, helping you understand why acrylic is almost always the best choice for your storage needs.

Weight Comparison

When it comes to comparing the weight of acrylic boxes with other materials, the difference is quite significant. Acrylic has a relatively low density, with a density of approximately 1.19 grams per cubic centimeter. In contrast, glass, a common alternative for boxes, has a density of around 2.5 grams per cubic centimeter. This means that an acrylic box of the same size and dimensions as a glass box would be about half the weight.

For example, consider a medium-sized display box used in a store. If the glass version weighs 5 kilograms, the acrylic equivalent would weigh only around 2.5 kilograms. This weight difference has a direct impact on transportation. Shipping companies often calculate costs based on the weight of the items being shipped. Using lighter acrylic boxes can lead to substantial savings in shipping fees, especially for businesses that frequently send products over long distances.

In addition to transportation, the lightweight nature of acrylic boxes also makes them more convenient to handle during use. In a retail store, employees can easily move and rearrange acrylic display boxes without the need for heavy-duty equipment or extra manpower. Similarly, at home, an acrylic storage box is much easier to lift and carry around compared to a heavier box made of materials like metal or thick glass. This convenience factor can make a big difference in day - to - day operations, whether it's in a commercial or residential setting.

Strength and Impact Analysis

Strength and impact resistance are crucial factors to consider when comparing acrylic boxes with other materials. Glass is well - known for its brittleness. In a simple drop test from a height of 1 meter, a glass box is highly likely to shatter into numerous sharp pieces. This not only results in the loss of the box itself but also poses a safety hazard, especially in areas where people are present.

On the other hand, acrylic boxes have a much higher impact resistance. They can withstand the same 1-meter drop test without breaking. In fact, acrylic's impact resistance is about 10 times that of glass. This makes acrylic boxes suitable for applications where there is a risk of accidental dropping or minor collisions. For instance, in a warehouse where boxes are frequently moved around by forklifts or other machinery, an acrylic box is less likely to be damaged during handling compared to a glass box.

When compared to some plastics, acrylic also holds its own. While there are high-impact plastics available, many common plastics have lower impact resistance than acrylic. For example, low - density polyethylene (LDPE) plastic boxes, which are often used for basic packaging, can crack or break more easily when subjected to impacts. In a study where different boxes were hit with a standardized force, acrylic boxes showed less deformation and no signs of cracking, while LDPE boxes had visible cracks and dents.

Cost Evaluation

The cost of acrylic boxes in comparison to other materials is a multifaceted aspect. Initially, the price of an acrylic box may seem higher than that of a cardboard or basic plastic box. For example, a simple cardboard storage box might cost a few dollars, while a similar-sized acrylic box could cost upwards of $10. However, when considering the long-term cost effectiveness, acrylic often proves to be a better option.

Cardboard boxes are inexpensive upfront, but they have a short lifespan. They can be easily damaged by moisture, wear and tear, and are not very durable in general. A business that uses cardboard boxes for product packaging may find that it needs to replace these boxes frequently, especially if the products are being shipped or handled regularly. Over a year, the cost of constantly replacing cardboard boxes can add up significantly.

In contrast, acrylic boxes, with their durability and resistance to damage, can be reused multiple times. A high-quality acrylic box used for product display in a store can last for years with proper care. Additionally, the maintenance cost of acrylic boxes is relatively low. As mentioned earlier, they are easy to clean, and with simple precautions, they can maintain their appearance and functionality for a long time. When factoring in the replacement and maintenance costs over a long period, the total cost of using acrylic boxes can be lower than that of using more inexpensive but less durable materials.

Long-Term Maintenance and Care

Acrylic display boxes deliver both protection and preservation, making them a reliable choice for both storage and display needs. When properly maintained, their durability and optical clarity can yield long-lasting results that stand the test of time. Acrylic thrives with basic, preventative care measures.

Consistent, well-planned maintenance routines play a huge role in keeping acrylic display cases looking their best while safeguarding their structural integrity. With regular, proper care and upkeep, acrylic boxes can remain in good condition for many years. This level of care ensures they stay bright, glossy, and fully functional—just as they were the day you first got them.

Simple Cleaning Techniques

Cleaning acrylic boxes is a straightforward process that doesn't require complex tools or harsh chemicals. For regular dust and dirt removal, start by using a soft, lint-free cloth, such as a microfiber cloth. Gently wipe the surface of the acrylic box to remove any loose particles. If there are stubborn stains or fingerprints, prepare a mild cleaning solution.

A mixture of warm water and a small amount of mild dish detergent works well. Dip the soft cloth into the solution, wring it out slightly to avoid dripping, and then gently wipe the stained areas. For example, if you have an acrylic display box in a store that has accumulated fingerprints from customers, this method can quickly restore its clarity.

Avoid using abrasive cleaners like scouring powders or steel wool, as they can scratch the surface of the acrylic, causing it to lose its transparency and luster. Similarly, stay away from strong chemicals such as ammonia-based cleaners, bleach, or solvents like acetone. These can react with the acrylic material, leading to cloudiness, discoloration, or even cracking.

For instance, using acetone to clean an acrylic box can cause the surface to become brittle and develop small cracks over time. After cleaning with the mild solution, rinse the cloth thoroughly with clean water and wipe the box again to remove any residue from the detergent. Finally, dry the box with a dry, soft cloth to prevent water spots.

Preventing Scratches and Damage

Preventing scratches and damage to acrylic boxes is crucial for maintaining their appearance and functionality. One of the primary ways to prevent scratches is to avoid contact with sharp objects. When storing items inside the acrylic box, make sure they don't have sharp edges or corners.

For example, if you're using an acrylic box to store tools, ensure that the tools are arranged in a way that they don't rub against the sides of the box. In a workshop, it's common to have small metal parts, and placing them carelessly in an acrylic storage box can lead to scratches.

When handling the acrylic box, always hold it by the edges or use both hands to support it evenly. Avoid dragging the box across rough surfaces, as this can cause scratches. If you need to move the box around frequently, consider using a protective mat or a soft-lined tray to place it on.

In a retail setting, when rearranging product displays, employees should be trained to handle acrylic boxes with care to prevent accidental scratches. Additionally, if the acrylic box has a lid, make sure it closes properly and doesn't rub against the sides of the box when opening and closing.

Extending Acrylic Box Lifespan

To extend the lifespan of an acrylic box, regular inspection is essential. Periodically check the box for any signs of wear and tear, such as small cracks, scratches, or discoloration. If you notice a small scratch early on, you can take steps to repair it before it worsens. For example, a small scratch can sometimes be buffed out using a specialized acrylic polishing compound and a soft cloth.

Avoid overloading the acrylic box. Each box has a recommended weight capacity, and exceeding this can put stress on the material, leading to cracks or deformation over time. In a storage facility, if an acrylic box designed to hold a certain weight of files is overfilled with heavy books, it may start to warp or develop cracks.

Also, when not in use, store the acrylic box in a clean, dry place away from direct sunlight and extreme temperatures. Sunlight can cause the acrylic to fade or yellow over time, while extreme heat or cold can affect its structural integrity. For instance, leaving an acrylic box in a hot attic during summer or a cold garage in winter can shorten its lifespan.

By following these simple maintenance and care tips, you can ensure that your acrylic box serves you well for a long time.

Environmental Impact on Acrylic Longevity

Acrylic boxes are valued for their durability and versatility, which makes them an excellent option for acrylic jewelry boxes. In reality, their performance and lifespan can be significantly affected by a range of environmental factors. Identifying these factors is crucial to maximizing the longevity of acrylic display boxes in different environments. By making wise decisions and taking careful care of acrylic boxes, they can stay crystal clear, sturdy, and usable for several decades.

UV Exposure Effects

UV exposure can have a significant impact on the longevity of acrylic boxes. When acrylic boxes are exposed to sunlight for extended periods, the ultraviolet (UV) rays in sunlight can cause a series of chemical reactions within the acrylic material. One of the most visible effects is yellowing. Over time, the surface of the acrylic box may gradually turn yellow, which not only affects its aesthetic appearance but also reduces its transparency. This is especially a concern for acrylic boxes used in product displays or in applications where clear visibility is crucial.

Moreover, long-term UV exposure can lead to the degradation of the acrylic's molecular structure. The high-energy UV photons can break the chemical bonds in the acrylic polymer chains, causing the material to become brittle and more prone to cracking. In an outdoor advertising application, where an acrylic display box is constantly exposed to sunlight, after a few years, the box may start to show signs of small cracks around the edges due to UV-induced degradation.

To mitigate these effects, manufacturers often add UV-resistant additives during the production of acrylic. These additives work by absorbing or reflecting the UV rays, preventing them from reaching the acrylic's molecular structure. Another option is to apply a UV-resistant coating to the surface of the acrylic box. This coating acts as a protective barrier, shielding the acrylic from UV damage. For outdoor - used acrylic boxes, choosing products with these UV-protection features can significantly extend their lifespan.

Temperature Change Considerations

Temperature changes can also pose challenges to the performance and longevity of acrylic boxes. Acrylic has a relatively high coefficient of thermal expansion, which means that it expands and contracts more than some other materials in response to temperature changes.

In high-temperature environments, acrylic boxes can start to deform. When the temperature approaches the heat-distortion temperature of acrylic (which is typically around 70 - 100°C depending on the grade of acrylic), the box may lose its original shape. For example, if an acrylic storage box is left in a hot car during summer, where the interior temperature can easily exceed 60°C, it may warp or bend out of shape. This deformation not only affects the functionality of the box but can also make it less visually appealing.

On the other hand, in low-temperature environments, acrylic becomes more brittle. When the temperature drops below a certain point, usually around - 20°C to - 30°C, the impact resistance of acrylic decreases significantly. A low - temperature - brittle acrylic box is more likely to crack or break when subjected to minor impacts or stress. In a cold storage facility where the temperature is maintained at a very low level, acrylic boxes used for storing items need to be carefully selected to ensure they can withstand the cold environment.

To address these temperature-related issues, it's important to choose the right type of acrylic for the intended temperature environment. Some acrylic materials are formulated to have better heat-resistance or cold-resistance properties. Additionally, proper insulation or temperature-control measures can be taken. For example, in a hot environment, providing shade or ventilation for the acrylic box can help keep it cool and prevent overheating. In a cold environment, using additional protective materials or keeping the box in a climate-controlled area can reduce the risk of cold-related damage.

Humidity and Moisture Influence

Humidity and moisture can have a notable impact on the lifespan of acrylic boxes. While acrylic is a water-resistant material, high humidity and prolonged exposure to moisture can still cause problems.

In high-humidity environments, moisture can condense on the surface of the acrylic box. If the box is not properly ventilated, this condensed moisture can lead to the growth of mold and mildew on the surface. Mold not only looks unsightly but can also be difficult to remove completely without damaging the acrylic surface. In a bathroom or a basement with high humidity levels, an acrylic storage box may be at risk of mold growth if it's not designed to handle such conditions.

Moreover, moisture can also seep into small cracks or joints in the acrylic box, especially if it's not well-sealed. Once inside, the moisture can cause corrosion of any metal components present in the box, such as hinges or fasteners. This corrosion can weaken the structural integrity of the box and lead to premature failure. For example, in an industrial setting where acrylic boxes are used to store metal parts and are exposed to humid air, the metal-acrylic interfaces need to be carefully protected to prevent corrosion.

To prevent the negative effects of humidity and moisture, proper ventilation should be ensured for acrylic boxes, especially in humid environments. Using sealed acrylic boxes or adding weather stripping to the edges can help keep moisture out. Additionally, regularly inspecting the box for any signs of moisture damage and promptly addressing any issues, such as cleaning mold or fixing leaks, can help extend its lifespan.

Innovation in Acrylic Box Design

Today’s acrylic boxes are a far cry from their predecessors, all thanks to breakthroughs in design and advancements in manufacturing technology. These innovations have transformed modern acrylic boxes into multifunctional solutions that cater to a wide range of needs—while still boasting an appealing aesthetic.

Contemporary acrylic boxes integrate technology with state-of-the-art functionality. This effective blend of practicality and elegance is what makes them top choices, extending their popularity well beyond the realm of the arts.

Modern Manufacturing Techniques

The enhanced quality and precision of acrylic boxes have been achieved through the advanced manufacturing technologies and highly efficient automated processes adopted by AM Acrylics. Technologies like laser cutting generate burr-free edges and dimensionally precise fits—an aspect that holds particular importance when developing custom solutions.

Precision engineering takes this manufacturing process a notch higher, allowing for more intricate designs and tailored features that align with detailed customer requirements. For instance, jewelry store retailers can place custom orders for acrylic display cases, complete with specialized compartments cut to showcase the sparkle and allure of individual pieces.

Automated processes have played a crucial role in establishing quality control measures and enhancing production consistency. They significantly lower the risk of human error, and the uniformity brought about by automation is essential for large-volume orders or retail display items.

Partnering with the right acrylic box manufacturers that utilize these innovative techniques—such as Custom Designs Boxes—ensures exceptional outcomes. Their expertise truly stands out thanks to their capability to custom-design acrylic boxes of any size or style, seamlessly integrating them into a store’s existing aesthetic.

Enhanced Functionality Features

Today’s innovative acrylic box designs incorporate add-ons that address the most frequent usability challenges. Removable compartments and dividers are growing increasingly popular—especially in jewelry boxes—providing a more customizable way to store items of varying sizes.

Modular designs, which allow for quick customization and reconfiguration, take the versatility of acrylic boxes to an even higher level. These features make acrylic boxes extremely appealing to both consumers and businesses seeking storage solutions that are as attractive as they are practical.

Chinese manufacturers of acrylic jewelry boxes offer highly competitive pricing along with extensive customization options. This would not be possible without their cutting-edge manufacturing technologies and rich industry experience.

Currently, these acrylic jewelry box products hold over 80% of the market share. They serve as a prime example of how creative functional enhancements can fulfill essential needs while maintaining a price point that delivers clear value.

Meeting Industry-Specific Needs

Acrylic boxes can be further tailored to suit specialized applications across various industries. Retailers gain advantages from display cases featuring printed designs that align with their brand identity, while the medical sector demands storage options that are both sterile and durable.

Artists and collectors seek unique solutions—ones that truly highlight their artwork or collections. Collaborating with experienced manufacturers like Jayi Acrylic helps you access solutions that meet these specific needs, all while placing customer-centered design principles at the forefront.

Conclusion

Acrylic boxes have emerged as a remarkable solution with a plethora of advantages across various domains. Their material properties, such as high transparency, lightweight design, and durability, make them stand out from other materials. The ease of cleaning, design versatility, and cost-effectiveness further contribute to their widespread appeal. Whether it's enhancing product display and branding in the commercial world, providing practical storage solutions at home, or meeting specific industry needs, acrylic boxes have proven their worth time and time again.

Despite some potential limitations, such as susceptibility to scratches, these can be effectively mitigated through proper care and the use of advanced coatings. The continuous innovation in acrylic box design, with modern manufacturing techniques and enhanced functionality features, is also expanding its applications and improving its performance.

When considering packaging, storage, or display options, acrylic boxes should be at the top of your list. Their combination of practicality, aesthetics, and long-term value makes them a smart choice. So, whether you're a business looking to make a statement with product displays or a homeowner seeking stylish and functional storage solutions, embrace the advantages of acrylic boxes and unlock a world of possibilities.

About Jayi Acrylic

Jayi Acrylic Industry Limited stands as a leading manufacturer of custom acrylic products in China, boasting over 20 years of rich experience in design and production. We specialize in delivering high-quality acrylic items, including various custom acrylic displays and custom acrylic boxes, along with comprehensive acrylic engineering solutions. To meet diverse customer needs, we also offer professional OEM and ODM services, cementing our reputation as a reliable partner in the acrylic industry.

Have Questions? Get A Quote

Want to Know More About Acrylic Boxes?

Click the Button Now.

If You Are in Business,You May Like:

Post time: Oct-28-2025