If you’re in the market for bulk custom acrylic display cases, you’ve likely noticed a wide range in pricing. From budget-friendly options to premium models, the cost can vary significantly, leaving many buyers wondering what drives these differences.

Acrylic display cases are popular for showcasing products, collectibles, and artifacts due to their clarity, durability, and versatility, but understanding the factors that influence their cost in bulk is key to making an informed purchase.

In this guide, we’ll break down the top factors that affect the price of bulk acrylic display cases, helping you navigate your options and find the best value for your needs.

1. Acrylic Quality and Thickness

One of the most significant factors impacting the cost of bulk acrylic display cases is the quality of the acrylic material itself. Acrylic, also known as PMMA (polymethyl methacrylate), is available in various grades, each with distinct properties that impact both performance and price.

Cast vs. Extruded Acrylic

Cast acrylic is manufactured by pouring liquid resin into molds, resulting in a more uniform material with better optical clarity, chemical resistance, and impact strength. It’s also easier to machine and polish, making it ideal for high-end display cases.

Extruded acrylic, on the other hand, is produced by melting acrylic pellets and forcing them through a die, a faster and more cost-effective process. While extruded acrylic is cheaper, it’s slightly less durable and may have minor imperfections in clarity.

Unsurprisingly, bulk orders using cast acrylic will cost more than those using extruded acrylic.

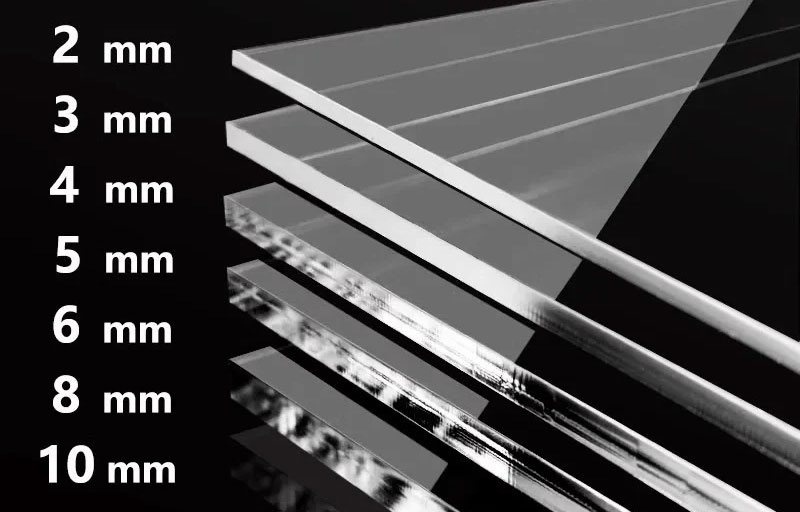

Thickness

The thickness of the acrylic sheets directly affects both cost and durability.

Thicker acrylic (e.g., 3mm, 5mm, or 10mm) is stronger and more resistant to cracking or warping, making it suitable for heavy or valuable items.

However, thicker sheets require more raw material and are more expensive to produce and ship.

For bulk orders, choosing the right thickness—neither too thin to risk damage nor too thick to inflate costs—is crucial.

2. Size and Complexity of Design

The size of the acrylic display cases and the complexity of their design play a major role in determining bulk costs.

Size

Larger cases require more acrylic material, which increases production costs.

Additionally, larger cases may be more challenging to handle during manufacturing, cutting, and assembly, leading to higher labor costs.

Shipping larger cases in bulk can also be more expensive due to increased weight and space requirements, especially for international orders.

Smaller, standard-sized cases, by contrast, are often cheaper to produce and ship in bulk, as they can be manufactured more efficiently and packed densely.

Design Complexity

Larger cases require more acrylic material, which increases production costs.

Additionally, larger cases may be more challenging to handle during manufacturing, cutting, and assembly, leading to higher labor costs.

Shipping larger cases in bulk can also be more expensive due to increased weight and space requirements, especially for international orders.

Smaller, standard-sized cases, by contrast, are often cheaper to produce and ship in bulk, as they can be manufactured more efficiently and packed densely.

3. Customization Options

Customization is a double-edged sword when it comes to bulk pricing: while it allows you to tailor cases to your specific needs, it can also drive up costs. Common customization options include:

Color

Clear acrylic is the most affordable, but colored or tinted acrylic (e.g., black, white, or custom Pantone colors) requires additional processing and may cost 10-30% more. Opaque colors or frosted finishes also add to production costs.

Printing or Branding

Adding logos, text, or graphics via screen printing, digital printing, or laser engraving increases labor and material costs. The more detailed the design, the higher the cost per unit. For bulk orders, some suppliers offer volume discounts on printed cases, but it’s still likely to be pricier than unbranded options.

Special Features

Custom hinges, locks, magnetic closures, or UV protection coatings enhance functionality but add to production time and material expenses. For example, UV-resistant acrylic, which prevents yellowing and protects displayed items from sunlight damage, is more expensive than standard acrylic.

4. Order Quantity

It’s no secret that bulk ordering typically leads to lower per-unit costs, but the relationship between order quantity and price isn’t always linear.

Suppliers often offer tiered pricing: the more units you order, the lower the cost per display case.

This is because larger orders allow manufacturers to optimize production runs, reduce setup times, and negotiate better prices for raw materials.

5. Supplier and Manufacturing Location

The choice of supplier and their manufacturing location can significantly impact the cost of bulk acrylic display cases.

Domestic vs. Overseas Suppliers

Domestic suppliers (e.g., in the U.S., Europe, or Canada) often charge more due to higher labor costs, stricter quality control standards, and shorter shipping times.

However, they may offer better communication, faster turnaround times, and easier resolution of issues like defects or returns.

Overseas suppliers, particularly in Asia, may offer lower per-unit prices due to lower labor and production costs, but they often require larger MOQs and longer shipping times.

Additionally, hidden costs like import taxes, customs fees, and shipping delays can erode the savings of overseas orders.

Supplier Reputation and Expertise

Established suppliers with a track record of producing high-quality acrylic products may charge more than newer or less reputable ones.

However, paying a premium for a reliable supplier can reduce the risk of receiving defective cases, which would cost more to replace in the long run.

Cheaper suppliers may cut corners on material quality or craftsmanship, leading to higher replacement costs over time.

Jayiacrylic: Your Leading Custom Acrylic Display Case Manufacturer

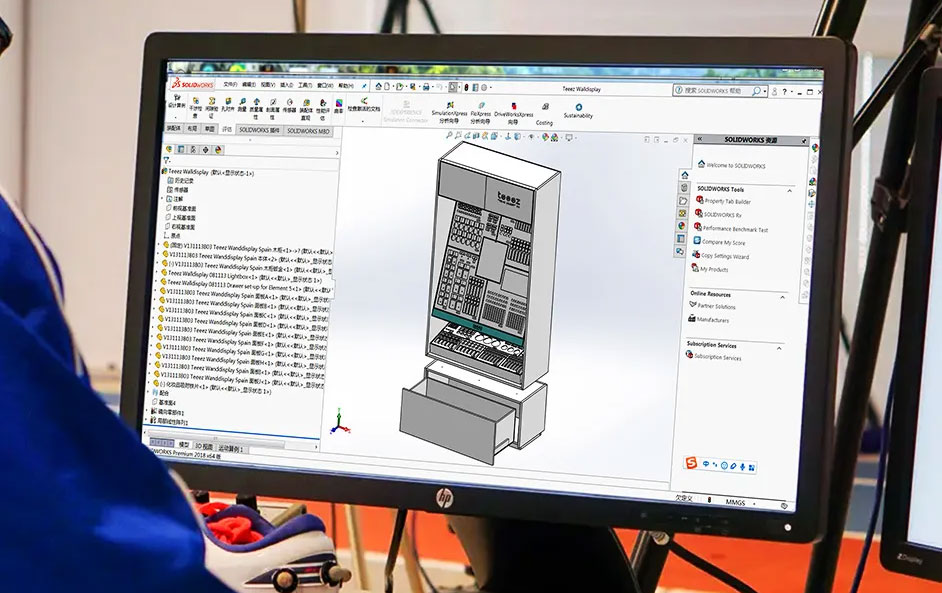

Jayi acrylic is a professional acrylic display case manufacturer in China. Jayi’s acrylic display cases are designed to meet diverse needs and deliver exceptional performance in commercial showcasing and personal collection applications. Our factory is certified with ISO9001 and SEDEX, ensuring superior quality and responsible production standards. Boasting over 20 years of collaboration with renowned brands, we deeply understand the importance of creating acrylic display cases that balance functionality, durability, and aesthetic appeal to satisfy both commercial and consumer demands.

6. Shipping and Packaging

Shipping costs are often overlooked but can add a significant amount to the total cost of bulk acrylic display cases, especially for large or heavy orders.

Shipping Method

Air freight is faster but much more expensive than sea freight, which is slower but more cost-effective for large bulk orders. Ground shipping is a middle option for domestic orders but varies in cost based on distance and weight.

Packaging

Acrylic is prone to scratching and cracking, so proper packaging is essential to prevent damage during transit. Custom packaging (e.g., foam inserts, protective sleeves) adds to costs but reduces the risk of returns or replacements. Some suppliers include basic packaging in their quotes, while others charge extra for premium protection.

Destination

Shipping to remote locations or countries with strict import regulations can increase costs due to additional fees, taxes, or surcharges. It’s important to factor these into your budget when comparing quotes from different suppliers.

7. Market Demand and Raw Material Prices

Like any product, the cost of acrylic display cases is influenced by market demand and the price of raw materials.

Acrylic Resin Prices

The cost of acrylic resin, the primary raw material used to make acrylic sheets, fluctuates based on supply and demand, global economic conditions, and energy prices (since resin production is energy-intensive). A spike in resin prices can lead to higher production costs, which suppliers may pass on to buyers.

Seasonal Demand

Demand for acrylic display cases tends to peak during certain times of the year, such as the holiday season, trade show seasons, or back-to-school periods. During these times, suppliers may raise prices due to increased demand, while off-peak seasons may offer lower prices and better deals.

How to Get the Best Value for Bulk Acrylic Display Cases

Now that you understand the key factors affecting cost, here are some tips to help you get the best value:

Compare Quotes

Get quotes from multiple suppliers, including both domestic and overseas options, to compare prices and services. Be sure to ask for detailed breakdowns of costs (material, labor, shipping, customization) to avoid hidden fees.

Opt for Standard Sizes and Designs

Whenever possible, choose standard sizes and simple designs to reduce costs. Only customize features that are essential for your use case.

Order in Larger Quantities:

Take advantage of tiered pricing by ordering the largest quantity you can reasonably afford to lower the per-unit cost.

Negotiate

Don’t be afraid to negotiate with suppliers, especially for large orders. Many suppliers are willing to offer discounts to secure bulk business.

Plan Ahead

Avoid rush orders, which often come with premium pricing. Planning allows you to choose slower, cheaper shipping methods and take advantage of off-peak pricing.

Prioritize Quality

While it’s tempting to choose the cheapest option, investing in higher-quality acrylic and craftsmanship can save you money in the long run by reducing the need for replacements or repairs.

Conclusion

The cost of bulk acrylic display cases is influenced by a variety of factors, from the quality and thickness of the acrylic to the complexity of the design, customization options, order quantity, supplier choice, shipping costs, and market conditions.

By understanding these factors, you can make informed decisions that balance your budget with your needs, ensuring you get durable, functional display cases at the best possible price.

Whether you’re a retailer showcasing products, a collector protecting valuables, or a business promoting your brand, taking the time to evaluate these factors will help you find the perfect bulk acrylic display cases for your requirements.

Acrylic Display Case: The Ultimate FAQ Guide

What Grades of Acrylic Do You Use for Bulk Display Cases, And How Does the Choice Affect Pricing?

We offer both cast and extruded acrylic. Cast acrylic, with superior clarity and durability, is ideal for high-end needs but costs 15-25% more than extruded acrylic. Extruded acrylic is more budget-friendly, suitable for standard use. Thickness (3mm-10mm) also impacts price—thicker sheets add 10-30% per unit due to extra material and handling.

Can You Provide Tiered Pricing for Bulk Orders, And What’s Your Minimum Order Quantity (Moq) for Custom Designs?

Our tiered pricing starts at 100 units ($15/unit), 500units($10/unit), and 1,000 units ($7/unit). For custom designs (e.g., engravings, special hinges), the MOQ is 300 units to optimize production efficiency. Orders below MOQ incur a 20% premium due to setup costs.

How Do Customization Options like Color, Printing, Or UV Coating Affect Bulk Costs?

Clear acrylic is base-priced. Colored/tinted options add 10-30%, while frosted finishes increase costs by 15%. Printing/engraving adds $2-5 per unit, depending on design complexity. UV-resistant coating, which prevents yellowing, adds 8-12% per unit but enhances longevity for displayed items.

What Shipping Methods Do You Offer for Bulk Orders, And How Do Destination and Packaging Choices Impact Costs?

We offer sea (most cost-effective for large bulk), air (faster but 3x pricier), and ground (domestic) shipping. Remote destinations or strict import regions add 10-20% in fees. Basic packaging is included, but foam inserts/sleeves for protection cost 0.50−2 per unit, reducing damage risks.

How Do Market Factors like Raw Material Prices or Seasonal Demand Affect Long-Term Bulk Pricing?

Acrylic resin price fluctuations (tied to energy costs) can adjust prices by 5-10% quarterly. Seasonal peaks (holidays, trade shows) may increase prices by 8-15% due to high demand. We recommend locking in prices with 3-month advance orders to avoid surcharges during busy periods.

You Might Also Like Custom Acrylic Display Cases

Post time: Aug-11-2025