Acrylic display cases play an important role in the business and personal field. They provide an elegant, transparent, and durable display space for displaying and protecting precious objects. Large acrylic display case is widely used in jewelry stores, museums, shopping malls, exhibitions personal collections displays, and other occasions. Not only do they attract the eye and highlight the beauty and value of the display, they also protect against dust, damage, and touch. The transparency and diverse design options of acrylic display cases make them ideal for displaying and displaying items, creating a compelling display effect and enhancing brand image and product value.

However, when customers come to us for design solutions, they inevitably have many questions about how to design and build the plexiglass display case they want. Then this article is for these customers to introduce how to make the perfect custom large plexiglass display cabinet. We will explore the key steps of the whole process from requirements determination to design, 3D modeling, sample making, production, and after-sales service.

Through this article, you will gain the expertise to make high-quality acrylic display cases and be able to make informed decisions in the customization process to meet your display needs and improve the display effect.

Step 1: Determine the Purpose and Requirements of Acrylic Display Cases

The first step is that we need to communicate with the customer in detail to understand their purpose and needs for the display case. This step is very simple, but it is crucial to ensure that the customer is satisfied with us. Jayi has 20 years of experience in customizing acrylic display cases, so we have accumulated a lot of expertise in transforming complex and infeasible designs into functional and beautiful display cases.

So in the process of communication with customers, we usually ask customers the following questions:

• In what environment are acrylic display cases used?

• How large are the items to be accommodated in the display case?

• How much protection do the items need?

• What level of scratch resistance does the enclosure need?

• Is the display case stationary or does it need to be removable?

• What color and texture do the acrylic sheet need to be?

• Does the display case need to come with a base?

• Does the display case need any special features?

• What is your budget for the purchase?

If you are in business, you may like

Acrylic Display Case With Base

Acrylic Display Case with Lock

Wall Acrylic Display Case

Rotating Acrylic Display Case

Step 2: Acrylic Display Case Design and 3D Modeling

Through the previous detailed communication with the customer, we have understood the customer's customization needs, then we need to design according to the customer's needs. Our design team draws custom-scale renderings. We then send it back to the customer for final approval and make the necessary adjustments.

Use Professional 3D Modeling Software to Create the Model of the Display Case

In the design and 3D modeling phase, we use professional 3D modeling software such as AutoCAD, SketchUp, SolidWorks, etc., to create models of the lucite display cases. This software provides a wealth of tools and functions that allow us to accurately draw the appearance, structure, and details of the display cases. By using this software, we can create highly realistic models of display cases so that customers can better understand the appearance and design of the final product.

Focus on Appearance, Layout, Functionality, and Details

During the design and 3D modeling of the display case, we focused on aspects such as appearance, layout, function, and detail. Appearance includes the overall appearance, material, color, and decoration of the perspex display case to ensure that it matches the customer's requirements and brand image. Layout involves the design of display items such as how they are displayed, internal partitions and drawers to provide the best display effect and organization.

The special requirements of display cases are considered in terms of functions, such as lighting, security, temperature and humidity control, etc. Details include processing edges, connection methods, opening and closing mechanisms, etc., to ensure that the structure of the display case is stable, easy to use and maintain.

Acrylic Display Case with Light

Feedback and Modification with Customers to Ensure Design Meets Expectations

The design and 3D modeling phases are important for feedback and modification with the customer. We share models of display cases with our customers and ask for their comments and suggestions. Customers can ensure that the design meets their expectations by observing the model, suggesting modifications and requests, etc. We actively listen to customer feedback and make modifications and adjustments based on their opinions to achieve the final design goal. This process of feedback and modification is repeated until the customer is satisfied to ensure that the final design is exactly consistent with the customer's needs.

Step 3: Acrylic Display Case Sample Production and Review

Once the customer approves their design, our expert craftsmen begin.

The process and speed vary depending on the acrylic type and the chosen base design. It usually takes us 3-7 days to make samples. Each display case is custom-made by hand, which is a great way for us to ensure customer satisfaction.

Make Physical Samples Based on 3D Models

Based on the completed 3D model, we will proceed with the fabrication of display case physical samples. This usually involves the use of suitable materials and tools to produce actual samples of the display case according to the dimensions and design requirements of the model. This can include fabrication using materials such as acrylic, wood, metal, and processes such as cutting, sanding, joining, etc. to achieve a realistic presentation of the model. The process of making samples requires the collaborative work of skilled workers and the production team to ensure the consistency of the physical sample with the 3D model.

Samples Were Reviewed to Assess Quality, Size, and Detail

Once the physical sample of the plexiglass display case is made, it will be reviewed to assess its quality, size, and details. During the review process, we carefully observe the appearance quality of the sample, including the smoothness of the surface, the accuracy of the edge, and the quality of the material. We will also use measuring tools to verify whether the size of the sample is consistent with the design requirements. In addition, we check detailed parts of the sample, such as connection points, decorative elements, and functional components, to ensure that it meets the design and customer expectations.

Make Necessary Adjustments and Improvements

In the process of reviewing the sample, some aspects may be found that need to be adjusted and improved. This may involve a few tweaks to the dimensions, modifications to the details, or changes to decorative elements. Based on the results of the review, we will discuss and formulate the necessary adjustments with the design team and production staff.

This may require additional fabrication work or the use of different materials to ensure that the sample can meet the final design criteria. This process of adjustment and improvement may require several iterations until the sample can fully meet the needs and expectations of the customer.

Step 4: Acrylic Display Case Production and Manufacturing

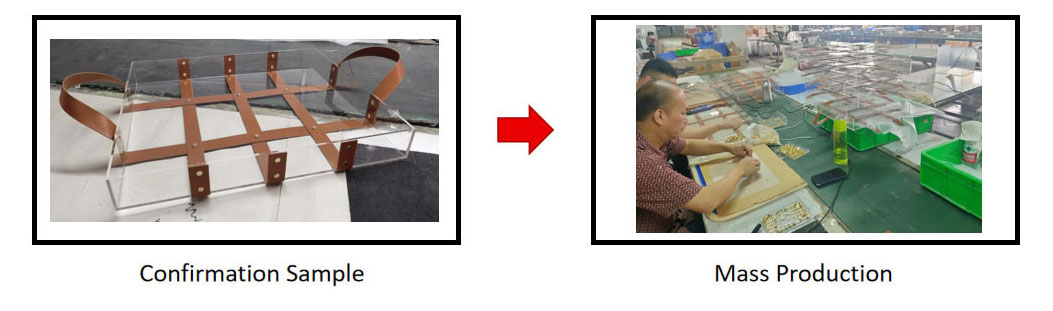

After the final sample is confirmed by the customer, we will arrange the sample for mass production.

Produce according to the final design and sample

After completing the final design and sample review, we will proceed with the production of the display case according to these identified schemes. According to the design requirements and the actual production of the samples, we will formulate the production plan and production process to ensure that the production is carried out according to the correct specifications and requirements.

Ensure production process quality control and delivery time compliance

During the production of the plexiglass display case, we will implement strict quality control measures to ensure that the quality of the final product meets expectations.

This includes quality inspection and testing at each production stage to verify the structural stability, appearance quality, and functionality of the display cases. We will also ensure that all materials and accessories used meet relevant standards and comply with the requirements of the quality management system.

In addition, we will strive to ensure the accuracy and reliability of the delivery time to meet the customer's time requirements.

Step 5: Acrylic Display Case Installation and After-Sales Service

Once the order has been created, completed, checked for quality, and carefully packed, it is ready to ship!

Provide Installation Guidance and Support

After the display case is delivered to the customer, we will provide detailed installation guidance and support. This may include providing installation manuals, drawings, and video tutorials to help customers properly install the display case. By providing clear installation instructions and professional service, we can ensure that customers can smoothly install display cabinets and avoid any errors or damage.

Provide After-Sales Service and Maintenance Advice

e are committed to providing comprehensive after-sales service and maintenance support. If customers encounter any problems or need help in the process of using the acrylic display cabinet, we will respond in time and provide solutions. We will provide maintenance advice, including the daily maintenance and cleaning methods of the display case to ensure its good condition and longevity. If more complex repairs or modifications are required, we will provide corresponding services to our customers and ensure their satisfaction.

By providing installation guidance and support, ensuring the stability and safety of the display case, and providing comprehensive after-sales service and maintenance advice, we can ensure that our customers receive comprehensive support and a satisfactory use experience after purchasing the display case. This helps build long-term customer relationships and maintain our reputation and credibility.

Summary

Making the perfect customized large acrylic display case requires careful demand analysis, precise design, professional manufacturing, and professional guidance in the installation process.

Through professional customization and service, Jayi acrylic display case manufacturers can meet customer needs and help customers improve product display effect. Create a perfect display space with high-quality display cabinets, add highlights to customers' products and brands, and help business success!

Customer Satisfaction Is Jayi's Goal

Jayi's business and design team actively listens to our clients' needs, works closely with them, and provides professional advice and support. Our team has the expertise and good communication skills to ensure that customer expectations are met.

By insisting on high quality and customer satisfaction, we can establish a good corporate image, build long-term customer relationships, and gain opportunities for word of mouth and business growth. This is the key to our success and an important factor in maintaining our competitive edge in the custom large acrylic display case market.

Post time: Mar-15-2024