In the dynamic world of custom-made products, bulk custom acrylic trays have gained significant popularity across various industries. Their versatility, durability, and aesthetic appeal make them a sought-after choice for businesses ranging from the food and beverage sector to retail and hospitality.

However, ordering acrylic trays in large quantities often comes with its fair share of quality issues. Understanding these common problems and knowing how to address them is crucial for ensuring that your investment results in high-quality, functional products.

1. Surface Imperfections: Scratches, Bubbles, and Dents

One of the most frequently encountered quality issues in bulk custom acrylic tray orders is surface imperfections. Scratches, bubbles, and dents can significantly mar the appearance of the trays and, in some cases, affect their functionality.

Scratches can occur during the manufacturing process, especially if the acrylic sheets are not handled with care. They can also happen during packaging, transportation, or storage.

Bubbles are often the result of improper mixing of the acrylic material or insufficient degassing during the casting or molding process.

Dents can be caused by external pressure during handling or shipping.

Solution

To minimize surface imperfections, it is essential to work with a reputable manufacturer who has strict quality control measures in place.

Request samples of the acrylic trays before placing a bulk order to inspect the surface quality.

During the manufacturing process, ensure that the acrylic sheets are protected with a scratch-resistant film.

For transportation and storage, use appropriate packaging materials, such as foam inserts and sturdy boxes, to prevent damage.

If surface imperfections are found upon receipt of the order, communicate promptly with the manufacturer to arrange for replacements or repairs.

2. Color Discrepancies

Another common quality issue is color discrepancies between the custom-ordered acrylic trays and the approved design or sample. This can be a significant problem, especially when the trays are intended for branding or promotional purposes.

Color discrepancies can occur due to several factors, including variations in the pigment used, differences in the manufacturing process, or inconsistencies in the lighting conditions during color matching. Even a slight deviation in color can make the trays look out of place or unprofessional.

Solution

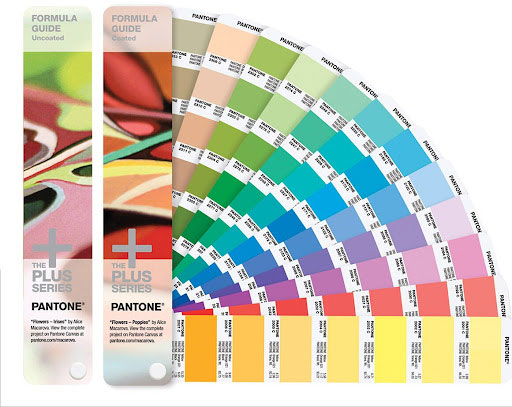

To avoid color discrepancies, provide the manufacturer with detailed color specifications, preferably in the form of a Pantone color code or a physical color sample.

Have a clear communication process in place to review and approve color samples before production begins.

It is also advisable to visit the manufacturing facility, if possible, to oversee the color-matching process.

If color discrepancies are detected in the final product, discuss with the manufacturer options for remanufacturing or adjusting the color.

3. Size and Shape Inaccuracies

Size and shape inaccuracies can render bulk custom acrylic trays unusable or less functional. Whether it's a tray that is too large or too small for its intended purpose or one with irregular shapes, these inaccuracies can cause significant problems for businesses.

Inaccuracies in size and shape can be due to errors in the design process, issues with the manufacturing equipment, or human error during cutting, shaping, or assembly. Even a minor deviation in dimensions can affect the tray's compatibility with other products or fixtures.

Solution

To ensure accurate size and shape, start with a detailed and precise design.

Use computer-aided design (CAD) software to create the design and provide the manufacturer with clear and detailed specifications.

During the manufacturing process, the manufacturer should use high-precision cutting and shaping equipment.

Regular quality checks should be conducted to verify that the trays meet the specified dimensions.

If size or shape inaccuracies are found, work with the manufacturer to correct the issue, which may involve remanufacturing the trays or making adjustments to the existing ones.

4. Structural Integrity Issues

Structural integrity is of utmost importance for acrylic trays, especially those that will be used to carry heavy or bulky items. Weak joints, thin or brittle material, and improper bonding can lead to trays that break or deform easily.

Structural integrity issues can arise from using low-quality acrylic material, improper manufacturing techniques, or insufficient reinforcement. For example, if the joints between different parts of the tray are not properly bonded, they may come apart under stress.

Solution

Select a manufacturer that uses high-quality acrylic materials and has expertise in manufacturing trays with strong structural integrity. Request information about the manufacturing process and the quality of the materials used.

During the design phase, consider adding reinforcements, such as additional supports or thicker sections, to areas of the tray that will bear the most weight.

Conduct stress testing on samples of the trays to ensure they can withstand the intended load.

If structural integrity issues are discovered in the bulk order, demand that the manufacturer take corrective action, which may include replacing the defective trays.

5. Uneven Finishing

Uneven finishing can make custom acrylic trays look unprofessional and reduce their overall appeal. This can include rough edges, uneven surfaces, or inconsistent polishing.

Uneven finishing is often the result of rushed manufacturing processes, inadequate quality control, or the use of substandard finishing equipment. Even if the basic shape and size of the tray are correct, a poor finish can significantly impact its quality.

Solution

Choose a manufacturer with a reputation for high-quality finishing.

Ensure that the manufacturing facility has the necessary equipment, such as polishing machines and edge-finishing tools, to achieve a smooth and even finish.

During the production process, conduct regular inspections to check the quality of the finishing.

If uneven finishing is found, the manufacturer should be required to re-finish the trays to meet the desired standards.

6. Printing and Engraving Defects

For custom acrylic trays with printed or engraved designs, printing and engraving defects can be a major concern. Blurred prints, missing details, or uneven engraving can make the trays fail to meet the branding or promotional requirements.

Solution

Work closely with the manufacturer to ensure that the printing and engraving processes are of high quality.

Provide high-resolution digital files for printing and clear specifications for engraving.

The manufacturer should use state-of-the-art printing and engraving equipment and high-quality inks and materials.

Request proof prints or samples of the engraved designs before mass production.

If printing or engraving defects are detected in the final product, the manufacturer should re - do the printing or engraving.

7. Chemical Resistance and Durability Concerns

In some applications, such as the food and beverage industry, chemical resistance and durability of acrylic trays are critical. If the trays are not resistant to common chemicals or do not have sufficient durability, they may degrade quickly, posing a safety risk and reducing their lifespan.

Chemical resistance and durability issues can be related to the type of acrylic material used, the manufacturing process, or the lack of proper treatment or coating. For example, if the acrylic is not formulated to resist certain cleaning chemicals, it may become discolored or damaged over time.

Solution

Select acrylic materials that are specifically designed for the intended application and have good chemical resistance and durability.

Consult with the manufacturer about the appropriate materials and treatments.

The manufacturer should conduct tests to ensure that the trays meet the required standards for chemical resistance and durability.

Provide the manufacturer with information about the specific chemicals and environmental conditions the trays will be exposed to.

If issues related to chemical resistance or durability are found, work with the manufacturer to find a solution, which may involve using different materials or applying additional coatings.

Choosing the Right Supplier

The key to avoiding quality issues often lies in selecting the right supplier. Here's what to consider:

Reputation and Reviews

Research potential suppliers thoroughly. Look for reviews that mention quality, consistency, and customer service. A supplier with a strong reputation is more likely to meet your quality expectations.

Evaluate suppliers based on their track record and feedback from previous clients. Consistent quality and excellent customer service are indicators of a reliable partner.

Consider reaching out to other businesses that have worked with potential suppliers to gather firsthand insights and recommendations. This networking can provide valuable information about the supplier's reliability.

Sample Orders

Before placing a bulk order, request samples. This allows you to assess the quality and make any necessary adjustments to your order specifications.

Review samples thoroughly, assessing their material quality, design accuracy, and overall finish. This evaluation is crucial for ensuring that the final product meets your standards.

Use the sample review process to communicate any adjustments or concerns to the supplier, fostering a collaborative relationship that aligns with your expectations.

Communication

Effective communication with your supplier is crucial. Clearly articulate your expectations and establish a line of communication for updates throughout the production process.

Maintain open channels of communication with your supplier, ensuring they understand your needs and can provide timely updates on your order's progress.

Set clear expectations from the outset, detailing your quality requirements, timelines, and any other relevant specifications. This clarity helps prevent misunderstandings and ensures a smooth collaboration.

Jayiacrylic: Your Leading China Custom Acrylic Tray Manufacturer And Supplier

Jayi Acrylic is a professional acrylic packaging manufacturer in China.

Jayi’s Custom Acrylic Tray solutions are meticulously crafted to captivate customers and showcase products most appealingly.

Our factory holds ISO9001 and SEDEX certifications, ensuring premium quality and ethical manufacturing standards.

With over 20 years of experience collaborating with leading global brands, we deeply understand the importance of designing custom vases that enhance product visibility and drive sales.

Our tailor-made options guarantee that your merchandise, decorative items, and valuables are presented flawlessly, creating a seamless unboxing experience that fosters customer engagement and boosts conversion rates.

How Can I Tell if a Manufacturer Is Reliable Before Placing a Bulk Order?

To determine a manufacturer's reliability, start by checking their online reviews and testimonials from previous clients.

Look for feedback specifically related to quality control and customer service in handling bulk acrylic tray orders.

Additionally, ask the manufacturer for references and contact past customers if possible. Inquire about their experience with the manufacturing process, adherence to deadlines, and how the manufacturer addressed any quality issues that arose.

A reliable manufacturer will also be willing to provide detailed information about their production methods, materials used, and quality assurance procedures, demonstrating their transparency and commitment to delivering high-quality products.

What Should I Do if I Notice Quality Issues After Receiving the Bulk Order?

As soon as you detect quality issues, document them thoroughly with clear photos and detailed descriptions.

Then, promptly contact the manufacturer's customer service department. Provide all the evidence you've gathered and clearly state your expectations, whether it's a replacement, repair, or partial refund.

Most reputable manufacturers have a defined process for handling such situations. Keep records of all communication, including emails, phone calls, and any agreements reached.

If the initial resolution isn't satisfactory, escalate the issue within the manufacturer's organization or consider involving a third-party mediator if necessary.

Can I Request a Sample of the Custom Acrylic Tray Before the Bulk Production?

Yes, you should always request a sample before placing a bulk order. A sample allows you to physically inspect the quality of the tray, check for surface imperfections, verify color accuracy, and assess the overall finish.

It also gives you a chance to test the tray's functionality if applicable. When requesting a sample, ensure that it is made using the same materials, processes, and specifications as the intended bulk order.

This way, you can make an informed decision and avoid potential quality issues in the final bulk production. If the sample doesn't meet your standards, work with the manufacturer to make adjustments before proceeding.

How Can I Ensure the Color of the Acrylic Trays Remains Consistent Throughout the Bulk Order?

To maintain color consistency, start by providing precise color specifications, such as Pantone codes, to the manufacturer. Have a pre-production approval process where you review and approve color samples under the same lighting conditions as where the trays will be used.

During production, the manufacturer should use a standardized color-mixing process and quality control checks at various stages. If possible, request that the manufacturer use the same batch of raw materials for your entire order to minimize variations.

Regularly communicate with the manufacturer during production to stay updated on color-related processes and address any concerns immediately.

What Are the Key Factors to Consider When Choosing Materials for Custom Acrylic Trays?

When selecting materials, consider the tray's intended use. For food-related applications, ensure the acrylic is food-grade and meets relevant safety standards.

Evaluate the material's durability, chemical resistance, and impact resistance. Thicker acrylic may be more suitable for trays that will carry heavy items.

UV-resistant acrylic is ideal if the trays will be exposed to sunlight to prevent yellowing or degradation.

Also, consider the clarity and color-fastness of the material.

Discuss your specific requirements with the manufacturer, who can recommend the most appropriate acrylic type based on your needs and budget.

Conclusion

Ordering bulk custom acrylic trays can be a cost-effective and rewarding way to meet your business needs.

However, being aware of the common quality issues and having effective solutions in place is essential.

By working with a reliable manufacturer, having clear communication, and implementing strict quality control measures, you can minimize the risk of quality problems and ensure that you receive high - quality, functional, and aesthetically pleasing acrylic trays.

Remember, a little extra effort in the planning and production process can go a long way in avoiding costly mistakes and ensuring customer satisfaction.

If You Are in Business,You May Like:

Post time: Jun-19-2025