When you walk through a store, you might pick up a clear box, a multi-functional display stand, or a colorful tray, and wonder: Is this acrylic or plastic? While the two are often lumped together, they’re distinct materials with unique properties, uses, and environmental impacts. Let’s break down their differences to help you tell them apart.

First, Let’s Clarify: Acrylic Is a Type of Plastic

Plastic is an umbrella term for a wide range of synthetic or semi-synthetic materials made from polymers—long chains of molecules. Acrylic, specifically, is a thermoplastic (meaning it softens when heated and hardens when cooled) that falls under the plastic family.

So, think of it like this: all acrylics are plastics, but not all plastics are acrylics.

Which Is Better, Plastic or Acrylic?

When choosing between acrylic and other plastics for a project, your specific needs are key.

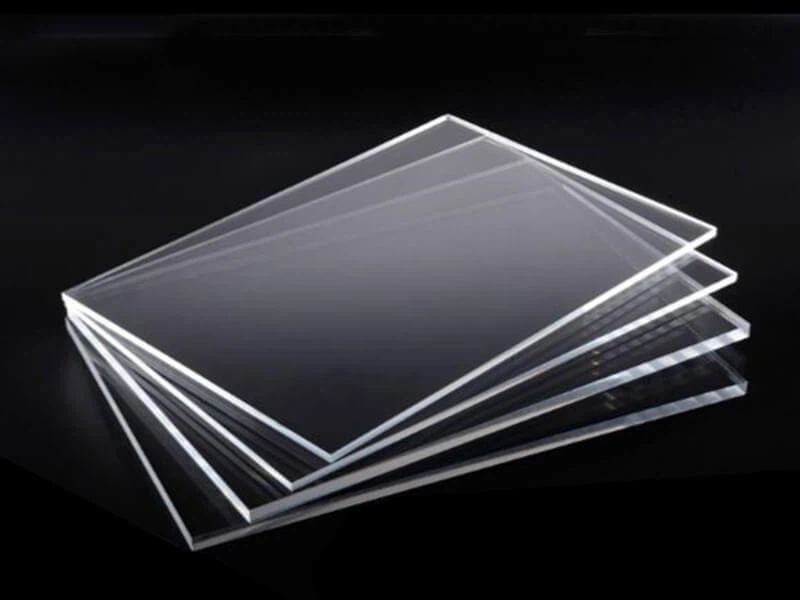

Acrylic excels in clarity and weather resistance, boasting a glass-like look paired with greater strength and shatter resistance. This makes it ideal for scenarios where transparency and durability matter—think display cases or cosmetic organizers, where its clear finish highlights items beautifully.

Other plastics, though, have their strengths. For applications needing flexibility or distinct thermal traits, they often outperform acrylic. Take polycarbonate: it’s a top pick when extreme impact resistance is critical, surpassing acrylic in withstanding heavy blows.

So, whether you prioritize a crystal-clear, sturdy surface or flexibility and unique heat handling, understanding these nuances ensures your material choice aligns perfectly with your project’s demands.

Key Differences Between Acrylic and Other Plastics

To understand how acrylic stands out, let’s compare it to common plastics like polyethylene (PE), polypropylene (PP), and polyvinyl chloride (PVC):

| Property | Acrylic | Other Common Plastics (e.g., PE, PP, PVC) |

| Transparency | Highly transparent (often called “plexiglass”), similar to glass. | Varies—some are opaque (e.g., PP), others are slightly transparent (e.g., PET). |

| Durability | Shatter-resistant, impact-resistant, and weatherproof (resists UV rays). | Less impact-resistant; some degrade in sunlight (e.g., PE becomes brittle). |

| Hardness | Hard and rigid, scratch-resistant with proper care. | Often softer or more flexible (e.g., PVC can be rigid or flexible). |

| Heat Resistance | Withstands moderate heat (up to 160°F/70°C) before softening. | Lower heat resistance (e.g., PE melts around 120°F/50°C). |

| Cost | Generally, more expensive due to manufacturing complexity. | Often cheaper, especially mass-produced plastics like PE. |

Common Uses: Where You’ll Find Acrylic Vs. Other Plastics

Acrylic shines in applications where clarity and durability matter:

• Windows, skylights, and greenhouse panels (as a glass substitute).

• Display cases, sign holders, and photo frames (for their transparency).

• Medical devices and dental tools (easy to sterilize).

• Golf cart windshield and protective shields (shatter resistance).

Other plastics are everywhere in daily life:

• PE: Plastic bags, water bottles, and food containers.

• PP: Yogurt cups, bottle caps, and toys.

• PVC: Pipes, raincoats, and vinyl flooring.

Environmental Impact: Are They Recyclable?

Both acrylic and most plastics are recyclable, but acrylic is trickier. It requires specialized recycling facilities, so it’s often not accepted in curbside bins. Many common plastics (like PET and HDPE) are more widely recycled, making them slightly more eco-friendly in practice, though neither is ideal for single-use products.

So, How to Tell Them Apart?

Next time you’re unsure:

• Check transparency: If it’s crystal clear and rigid, it’s likely acrylic.

• Test flexibility: Acrylic is stiff; bendable plastics are probably PE or PVC.

• Look for labels: “Plexiglass,” “PMMA” (polymethyl methacrylate, acrylic’s formal name), or “acrylic” on packaging are dead giveaways.

Understanding these differences helps you choose the right material for projects, from DIY crafts to industrial needs. Whether you need a durable window or a cheap storage bin, knowing acrylic vs. plastic ensures you get the best fit.

What Is the Disadvantage of Acrylic?

Acrylic, despite its strengths, has notable drawbacks. It’s more expensive than many common plastics like polyethylene or polypropylene, raising costs for large-scale projects. While scratch-resistant, it’s not scratch-proof—abrasions can mar its clarity, requiring polishing for restoration.

It’s also less flexible, prone to cracking under excessive pressure or bending, unlike pliable plastics such as PVC. Though heat-resistant to a degree, high temperatures (over 70°C/160°F) cause warping.

Recycling is another hurdle: acrylic needs specialized facilities, making it less eco-friendly than widely recyclable plastics like PET. These limitations make it less suitable for budget-sensitive, flexible, or high-heat applications.

Are Acrylic Boxes Better Than Plastic?

Whether acrylic boxes are better than plastic ones depends on your needs. Acrylic boxes excel in transparency, offering glass-like clarity that showcases contents, ideal for display cases or cosmetic storage. They’re also shatter-resistant, durable, and weatherproof, with good UV resistance, making them long-lasting for both indoor and outdoor use.

However, plastic boxes (like those made from PE or PP) are often cheaper and more flexible, suiting budget-friendly or lightweight storage. Acrylic is pricier, less bendable, and harder to recycle. For visibility and sturdiness, acrylic wins; for cost and flexibility, plastic may be better.

Acrylic and Plastic: The Ultimate FAQ Guide

Is Acrylic More Durable Than Plastic?

Acrylic is generally more durable than many common plastics. It’s shatter-resistant, impact-resistant, and better at withstanding weather (like UV rays) compared to plastics such as PE or PP, which can become brittle or degrade over time. However, some plastics, like polycarbonate, may match or exceed their durability in specific scenarios.

Can Acrylic Be Recycled like Plastic?

Acrylic can be recycled, but it is harder to process than most plastics. It requires specialized facilities, so curbside recycling programs rarely accept it. In contrast, plastics like PET (water bottles) or HDPE (milk jugs) are widely recyclable, making them more eco-friendly in everyday recycling systems.

Is Acrylic More Expensive Than Plastic?

Yes, acrylic is typically more expensive than common plastics. Its manufacturing process is more complex, and its high transparency and durability add to production costs. Plastics like PE, PP, or PVC are cheaper, especially when mass-produced, making them better for budget-sensitive uses.

Which Is Better for Outdoor Use: Acrylic or Plastic?

Acrylic is better for outdoor use. It resists UV rays, moisture, and temperature changes without cracking or fading, making it ideal for outdoor signs, windows, or furniture. Most plastics (e.g., PE, PP) degrade in sunlight, becoming brittle or discolored over time, limiting their outdoor lifespan.

Are Acrylic and Plastic Safe for Food Contact?

Both can be food-safe, but it depends on the type. Food-grade acrylic is non-toxic and safe for items like display cases. For plastics, look for food-safe variants (e.g., PP, PET) marked with recycling codes 1, 2, 4, or 5. Avoid non-food-grade plastics (e.g., PVC) as they may leach chemicals.

How Can I Clean and Maintain Acrylic Products?

To clean acrylic, use a soft cloth and mild soap with lukewarm water. Avoid abrasive cleaners or rough sponges, as they scratch the surface. For stubborn dirt, gently wipe with a microfiber cloth. Avoid exposing acrylic to high heat or harsh chemicals. Regular dusting helps maintain its transparency and longevity.

Are There Any Safety Concerns When Using Acrylic or Plastic?

Acrylic is generally safe, but may release fumes when burned, so avoid high heat. Some plastics (e.g., PVC) can leach harmful chemicals like phthalates if heated or worn. Always check for food-grade labels (e.g., acrylic or plastics marked #1, #2, #4) for items in contact with food to avoid health risks.

Conclusion

The choice between acrylic and other plastics hinges on your specific needs. If clarity, durability, and aesthetics are paramount, acrylic is an excellent pick—it offers glass-like transparency and long-lasting sturdiness, ideal for displays or high-visibility uses.

However, if flexibility and cost matter more, other plastics often excel. Materials like PE or PP are cheaper and more pliable, making them better suited for budget-focused or flexible applications where transparency is less critical. Ultimately, your priorities guide the best choice.

Jayiacrylic: Your Leading China Custom Acrylic Products Manufacturer

Jayi acrylic is a professional acrylic products manufacturer in China. Jayi’s acrylic products are designed to meet diverse needs and deliver exceptional performance in daily use and industrial applications. Our factory is certified with ISO9001 and SEDEX, ensuring superior quality and responsible production standards. Boasting over 20 years of collaboration with renowned brands, we deeply understand the importance of creating acrylic products that balance functionality, durability, and aesthetic appeal to satisfy both commercial and consumer demands.

You Might Also Like Other Custom Acrylic Products

Post time: Jul-10-2025